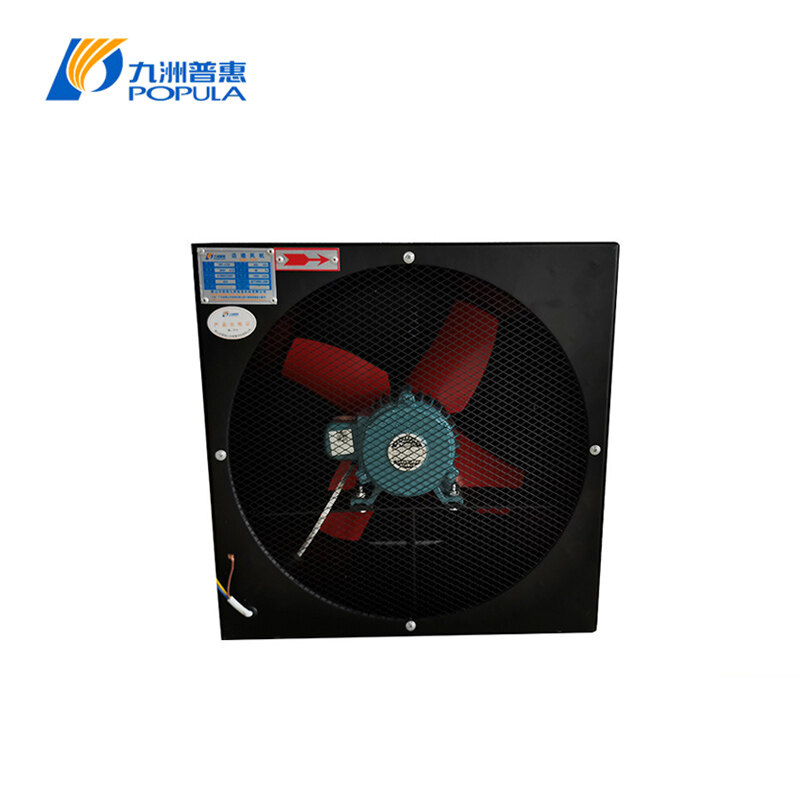

JS Square Fan Features:

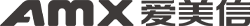

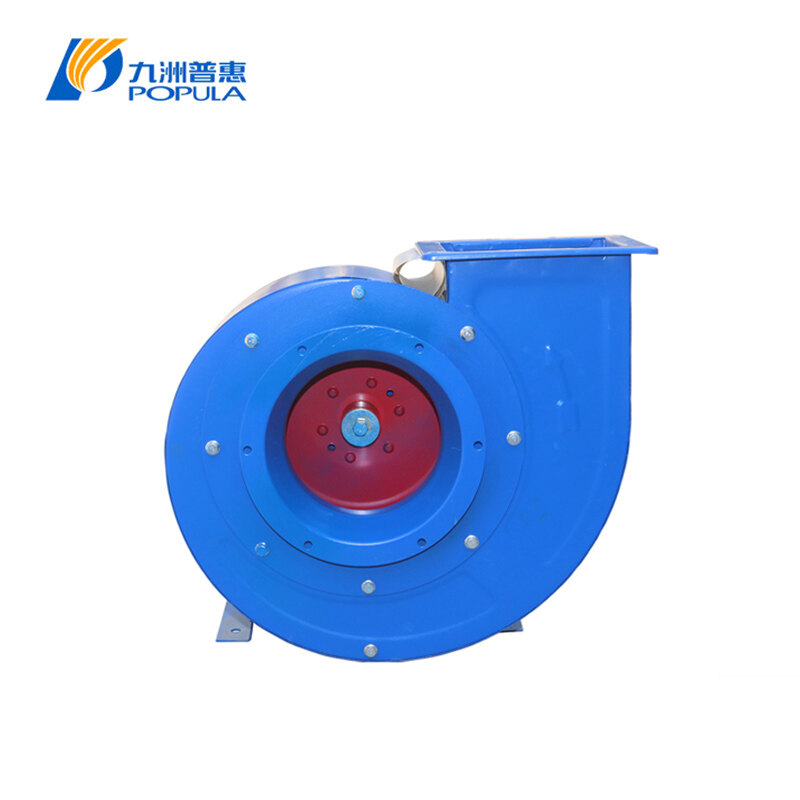

: Material Properties

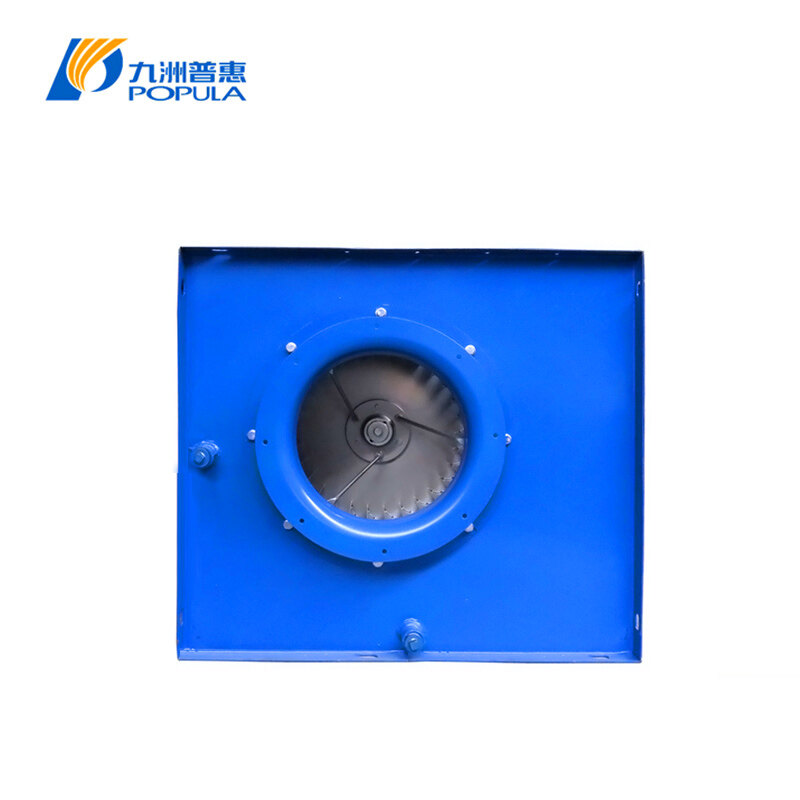

: The case is made of galvanized steel sheet with electrostatic powder coating. The propeller is made of aluminium and iron material. Which means it has a degree of corrosion resistance property. The temperature tolerance is under or equal to 70ºC. While it still working under the humidity of 90%. It is ideal for greenhouse exhausting or ventilation. To go more detail, the fan has protective nets on both sides or you can choose to put louver at the front for safety reasons. The product is used to transport non-flammable,low-corrosive gases with the temperature no higher than50℃. The air relative humidity no greater than 80% and the quantity of dust and solid impurities ≤150mg/m3

: Fan Structure

: Either A type or C type of driven type is available to choose. The propeller design is called composite twisted blades. Meanwhile tested by a static equilibrium experiment. The rotation speed is relatively low for the C type (belt-driven type) model, which gives more flexibility to adjust the fan vibrancy or tension. Therefore, the C type can be customised and suitable for different voltage and frequencies nicely. The design of the fan has A: 4, 5, 6, 7, 8, 9, 10, 12, 13 eight; C has: 8, 9, 10, 10, 12, etc. Through static balance test, the impeller work is low (the motor passes through the wheel drive) and the motor seat can be vibration damping and automatic tensioning through the spring.

: Usage Areas

: Factory, warehouse, office, greenhouse, stocks house etc. It is ideal for cooling and ventilation purposes. Features by low noise, less electricity consumption, large air volume, long delivery distance, and easy installation.

The fans house and motor can be guranteed for 1 year.

JS Negative Pressure Square Exhaust Fan (Motor in the Middle):

| Model | Type | Power (KW) |

Voltage ( V ) |

RPM (r/min) |

Volume(m³/h) |

| JS-II-4A | With Louver | 0.37 | 380 | 1400 | 7200 |

| JS-II-5A | 0.55 | 380 | 1400 | 8600 | |

| JS-II-6A | 0.25 | 380 | 720 | 17000 | |

| JS-II-8A | 0.4 | 380 | 520 | 23000 | |

| JS-II-9A | 0.55 | 380 | 520 | 27500 | |

| JS-II-10A | 0.55 | 380 | 460 | 32000 | |

| JS-II-12A | 0.75 | 380 | 460 | 37000 | |

| JS-II-13A | 1.1 | 380 | 460 | 44500 | |

| JS-II-6A | Both Nets | 0.25 | 380 | 720 | 17000 |

| JS-II-8A | 0.4 | 380 | 520 | 23000 | |

| JS-II-9A | 0.55 | 380 | 520 | 27500 | |

| JS-II-10A | 0.55 | 380 | 460 | 32000 | |

| JS-II-12A | 0.75 | 380 | 460 | 37000 | |

| JS-II-13A | 1.1 | 380 | 460 | 44500 |

| Model | Type | Power (KW) |

Voltage ( V ) |

RPM (r/min) |

Volume(m³/h) |

| JS-II-8C | With Louver | 0.55 | 380 | 520 | 23000 |

| JS-II-9C | 0.75 | 380 | 520 | 27500 | |

| JS-II-10C | 0.75 | 380 | 460 | 32000 | |

| JS-II-12C | 1.1 | 380 | 460 | 37000 | |

| JS-II-13C | 1.1 | 380 | 460 | 44500 | |

| JS-II-8C | Both Nets | 0.55 | 380 | 520 | 23000 |

| JS-II-9C | 0.75 | 380 | 520 | 27500 | |

| JS-II-10C | 0.75 | 380 | 460 | 32000 | |

| JS-II-12C | 1.1 | 380 | 460 | 37000 | |

| JS-II-13C | 1.1 | 380 | 460 | 44500 |