Low Noise Duct Fan | Centrifugal Fan Blower Manufacturers - AMX

CF Model Features:

Material Properties

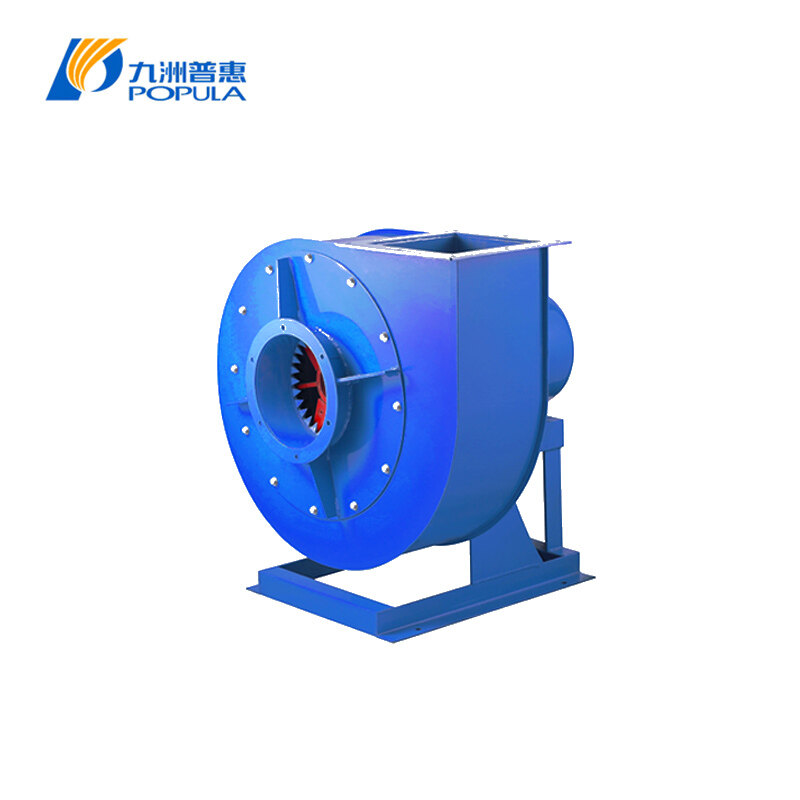

During the design process, we used multi-objective optimization for noise and efficiency to achieve the best performance. It’s with good aerodynamic performance.

It can be used in many factories which have some paper that needs to be made up together. This blower is designed with 8 sizes like No. 1.5, 2, 2.5, 3, 3.5, 4, 4.5, 5. There’s dextrorotation and levorotation for the impeller rotating direction

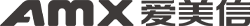

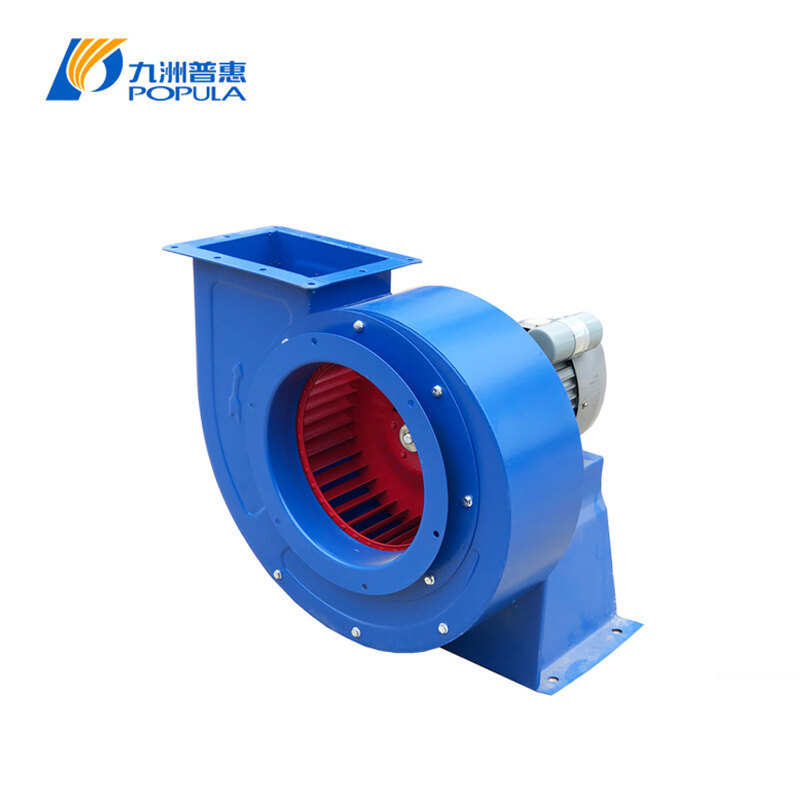

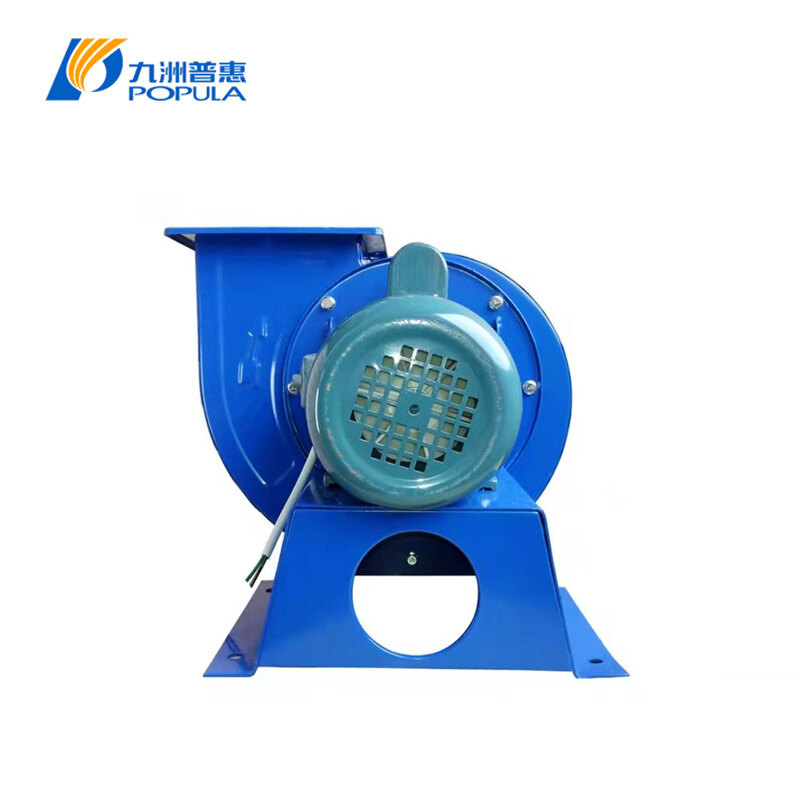

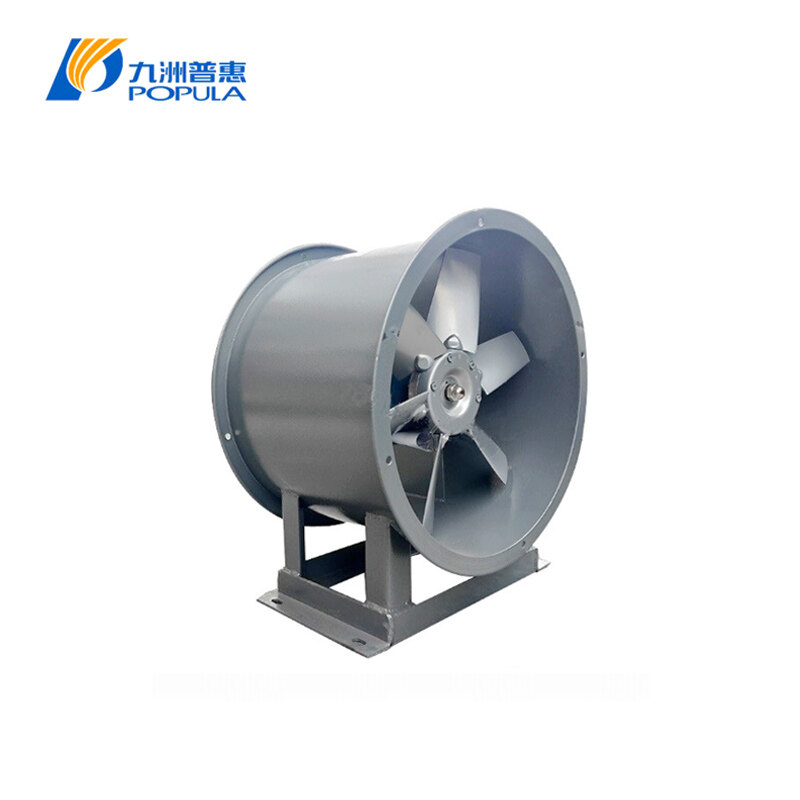

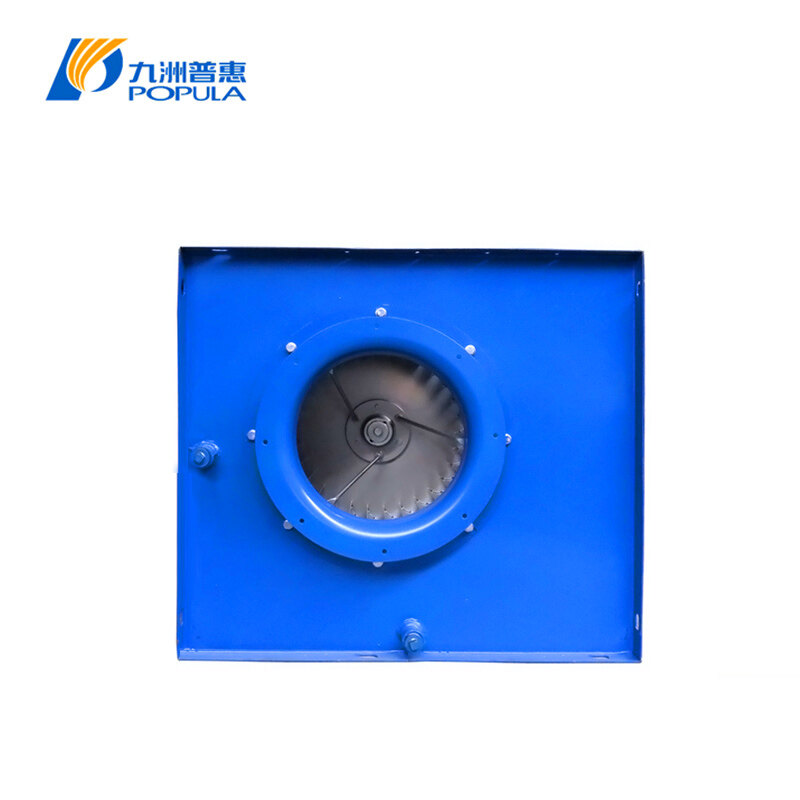

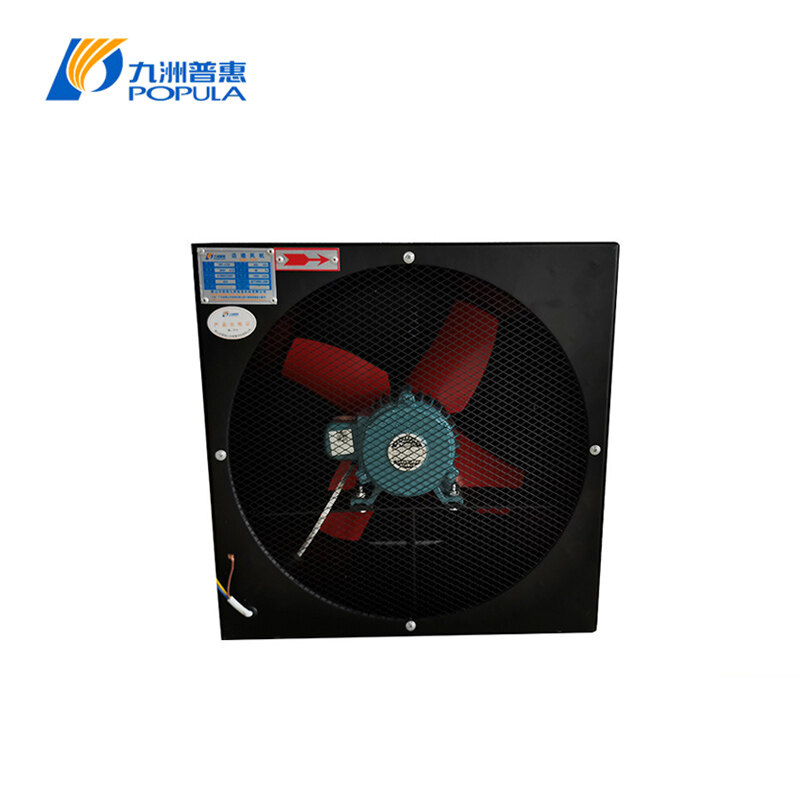

Fan Structure

This blower is composed of Inlet, Impeller, Casing, and Motor.

Impeller: Made of high-quality steel plate, Riveted with 40-80 thin arc impeller, hub and hub cover. This industrial centrifugal fan is balanced well statically and dynamically, which gives it good aerodynamic performance, low noise, and stable operation.

Casing: The whole casing of this low noise duct fan is welded with a high-quality steel plate. The spiral tongue is a new type of noise elimination structure that lowers noise.

Inlet: Weld convergent clipper-built normal steel plate with front cover together.

Installation

Install the fan according to the pictures, make sure that the shell is clean inside out, and maintain the balance of the fan while installing it; the contact surface between the fan and the base the connections between the inlet pipe and the fan should be fixed with each other naturally, don’t force them, it's forbidden to transfer the pipe's weight on the fan, and ensure the balance of the fan.

Operating

After the installation and the inspection, we will have a test run, and it should be under no-load condition by closing all air inlet valves, then turning into full-load according to the operating situation by open all air inlet valves; the test run for new fan, and the fan after repairing can’t be lessor than 2 hours.

Maintenance

The maintenance can only be done when the fan is stopped to ensure safety. After the maintenance please remember to have a test run first before operating it. And also, remember to clean the dust, dirt and other impurities regularly. If the fan is using in kitchen or spraying occasion, please clean the impeller every 60 days, otherwise it will cause the overloading of the fan by damage the motor and reduce the air volume.

| Model | Power (KW) |

Voltage (V) |

RPM (r/min) |

Volume(m³/h) | Pressure(Pa ) |

| 1.5A | 0.37 | 220 | 2800 | 830~1080 | 790~748 |

| 0.37 | 380 | 2800 | 830~1080 | 790~748 | |

| 2A | 1.1 | 220 | 2800 | 1248~2258 | 1150~839 |

| 1.1 | 380 | 2800 | 1248~2258 | 1150~839 | |

| 0.37 | 220 | 1400 | 650~1125 | 248~210 | |

| 0.37 | 380 | 1400 | 650~1125 | 248~210 | |

| 2.5A | 2.2 | 220 | 2800 | 748~2617 | 1542~1296 |

| 2.2 | 380 | 2800 | 748~2617 | 1542~1296 | |

| 0.75 | 220 | 1400 | 1400~2300 | 377~320 | |

| 0.75 | 380 | 1400 | 1400~2300 | 377~320 | |

| 0.55 | 220 | 1400 | 1500~2200 | 367~312 | |

| 0.55 | 380 | 1400 | 1500~2200 | 367~312 | |

| 3A | 1.5 | 220 | 1400 | 2033~3500 | 800~715 |

| 1.5 | 380 | 1400 | 2033~3500 | 800~715 | |

| 1.1 | 220 | 1400 | 1960~3300 | 810~750 | |

| 1.1 | 380 | 1400 | 1960~3300 | 810~750 | |

| 0.75 | 380 | 910 | 1300~2252 | 350~315 | |

| 3.5A | 3 | 220 | 1420 | 3233~5000 | 1050~800 |

| 3 | 380 | 1420 | 3233~5000 | 1050~800 | |

| 2.2 | 220 | 1420 | 3000~4800 | 1032~900 | |

| 2.2 | 380 | 1420 | 3000~4800 | 1032~900 | |

| 1.1 | 380 | 910 | 2300~3150 | 460~385 | |

| 4A | 4 | 380 | 1450 | 4000~6500 | 1300~980 |

| 1.1 | 380 | 910 | 2500~4200 | 600~520 | |

| 4.5A | 3 | 380 | 960 | 4500~6500 | 764~630 |