Centrifugal Fan Blower | Industrial Steam Exhaust Fan - AMX

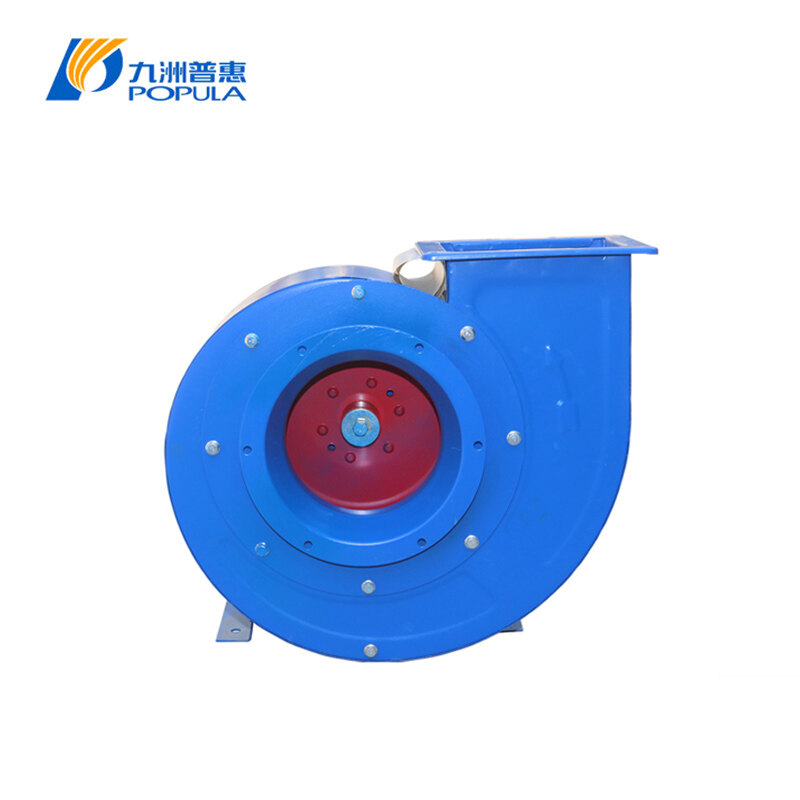

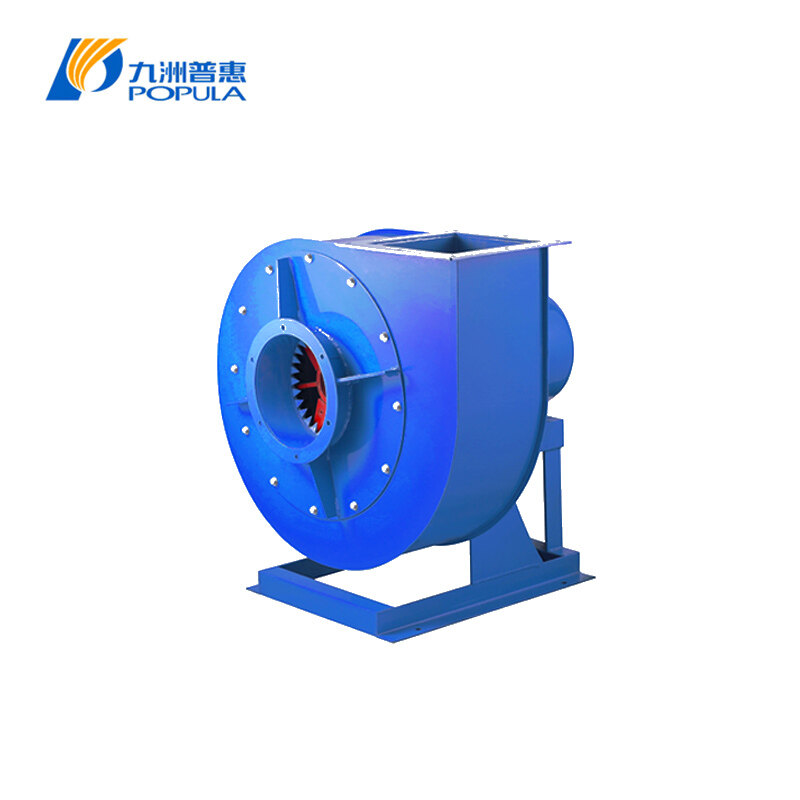

Middle Pressure Blower Features:

Material Properties

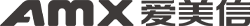

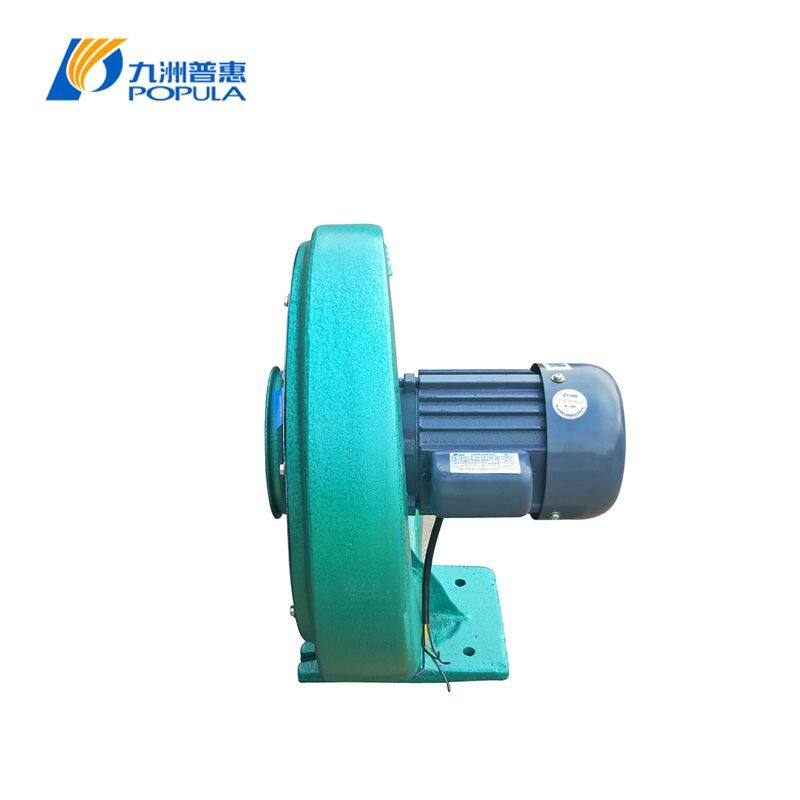

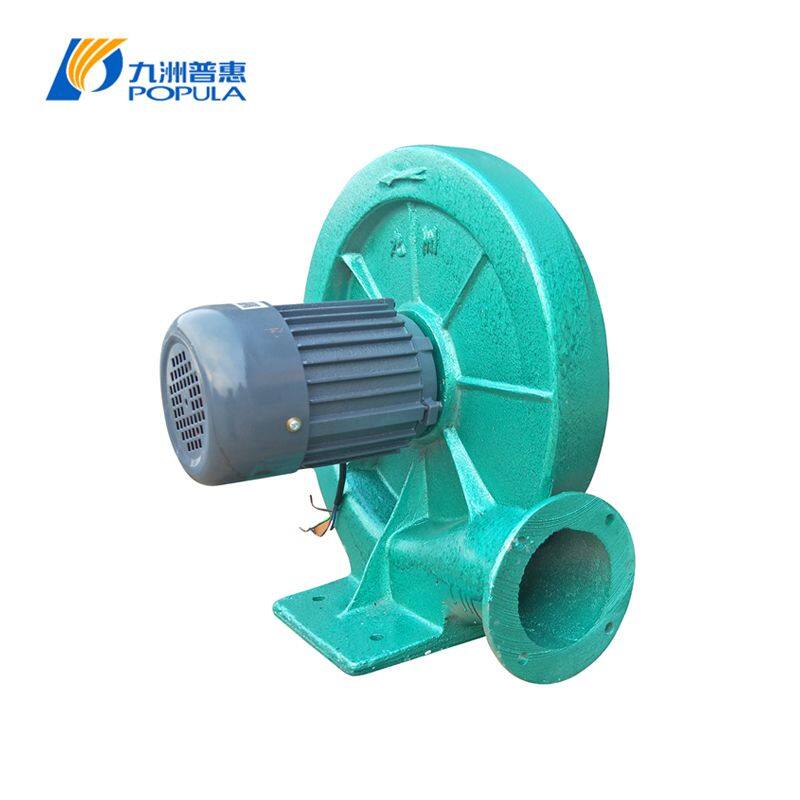

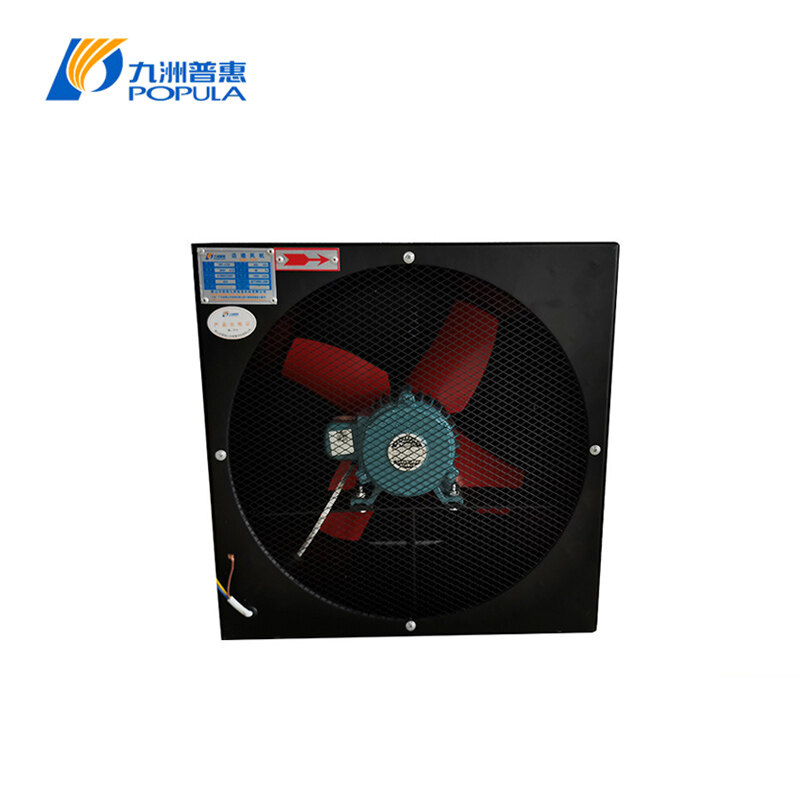

The case of this centrifugal fan blower can either be made of aluminum alloy or iron steel sheet with a circular air inlet as the convergent streamlined overall structure. Featured by lightweight, novel design, large air volume, and low noise. The adopted temperature is no higher than 80ºC.

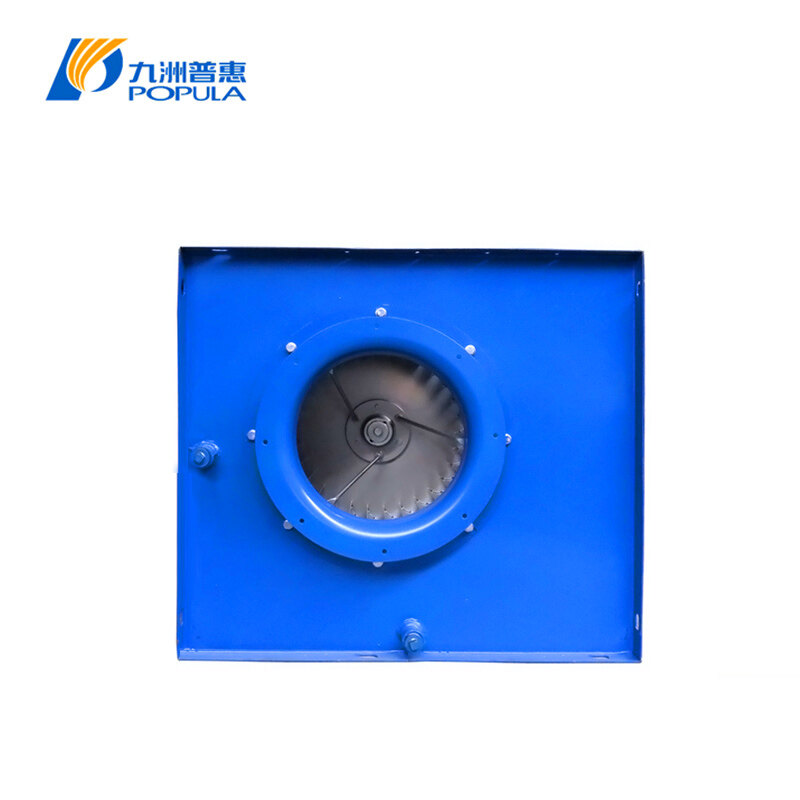

Fan Structure

The impeller of this industrial steam exhaust fan is semi-open, with a filed surface and corrected by static and dynamic balance, with good aerodynamic performance and smooth running. A new type of anechoic structure is used in the air outlet part of the housing, which has a good anechoic effect.

Maintenance

When maintaining the fan, you must power it off to ensure the safety of the people and the device. Repaired fans must be tested before they can be put into operation. Regularly clean the fan's internal ash, dirt, and other impurities. Fans used for kitchen smoking and other similar occasions should often clean the impeller, in general, within 60 days to clean once, otherwise it will cause the impeller overload and burn the motor and affect the air volume.

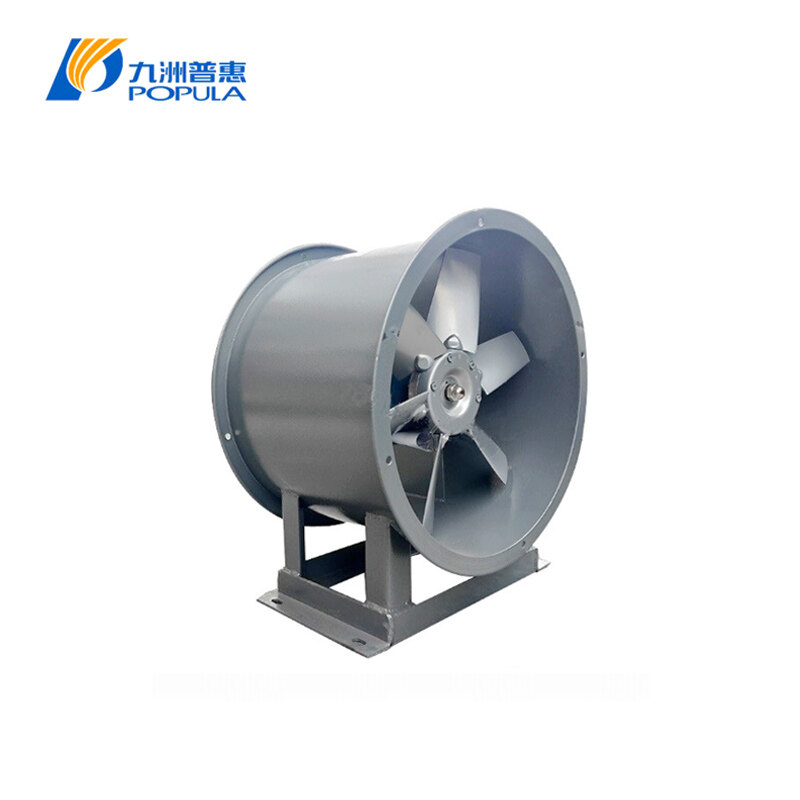

Usage Area

This centrifugal fan blower is used in some industrial devices to blow air, such as smelting, diesel vaporization heater matching, kitchen equipment, pneumatic compression facilities, industrial boilers, and plastics machinery.

| Model | Power (KW ) |

Voltage ( V ) |

RPM (r/min) |

Volume(m³/h) | Pressure(Pa) |

| 180W | 0.18 | 220 | 2800 | 408 | 1100 |

| 0.18 | 380 | 2800 | 408 | 1100 | |

| 250W | 0.25 | 220 | 2800 | 450 | 1200 |

| 0.25 | 380 | 2800 | 450 | 1200 | |

| 370W | 0.37 | 220 | 2800 | 690 | 1880 |

| 0.37 | 380 | 2800 | 690 | 1880 | |

| 550W | 0.55 | 220 | 2800 | 960 | 1980 |

| 0.55 | 380 | 2800 | 960 | 1980 | |

| 750W | 0.75 | 220 | 2800 | 1170 | 2140 |

| 0.75 | 380 | 2800 | 1170 | 2140 | |

| 900W | 0.9 | 220 | 2800 | 1320 | 2140 |

| 0.9 | 380 | 2800 | 1320 | 2140 | |

| 1100W | 1.1 | 220 | 2800 | 1404 | 2180 |

| 1.1 | 380 | 2800 | 1404 | 2180 | |

| 1500W | 1.5 | 220 | 2800 | 1530 | 2400 |

| 1.5 | 380 | 2800 | 1530 | 2400 | |

| 2200W | 2.2 | 220 | 2800 | 1560 | 2500 |

| 2.2 | 380 | 2800 | 1560 | 2500 | |

| 3000W | 3 | 380 | 2900 | 1620 | 2650 |