Smoke Centrifugal Fan | Centrifugal Fan And Rotary Blower - AMX

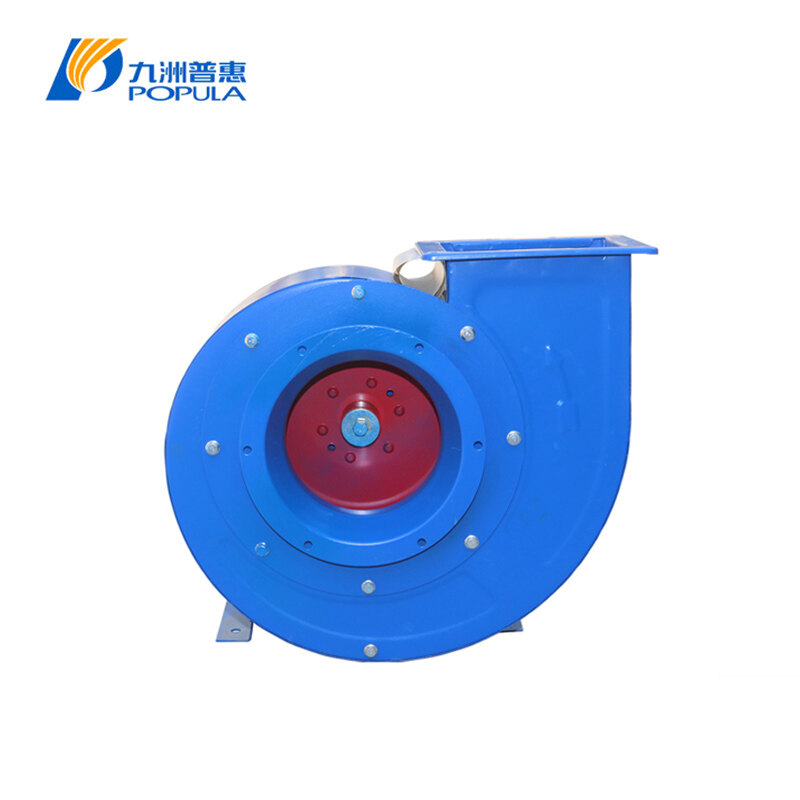

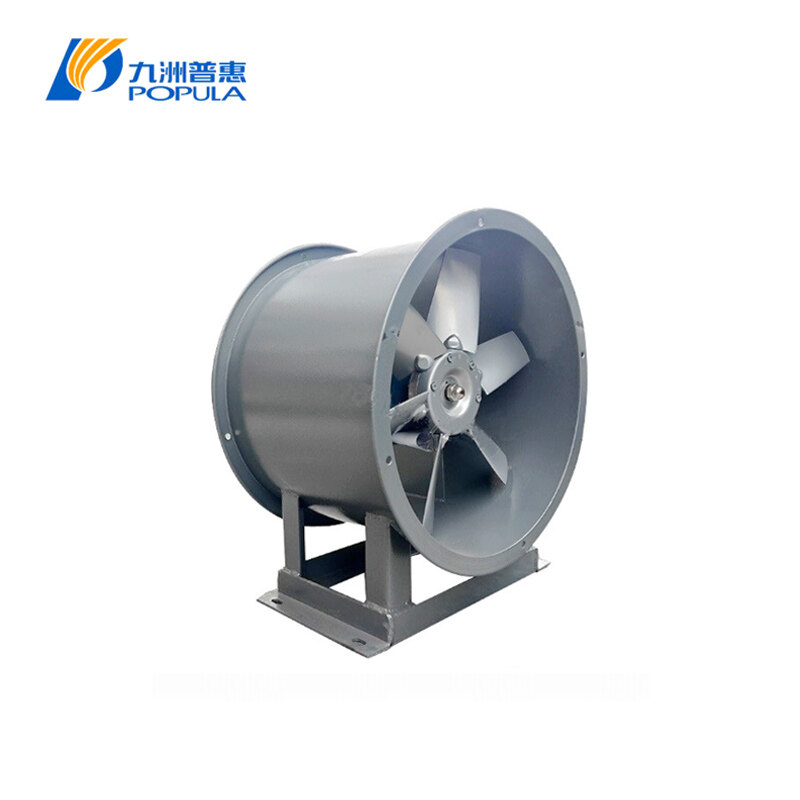

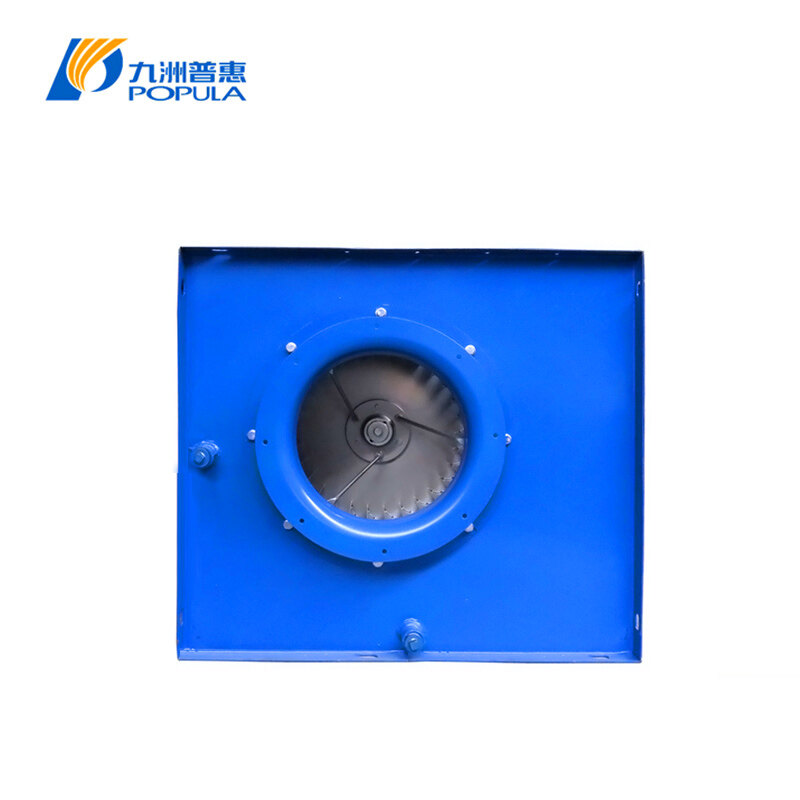

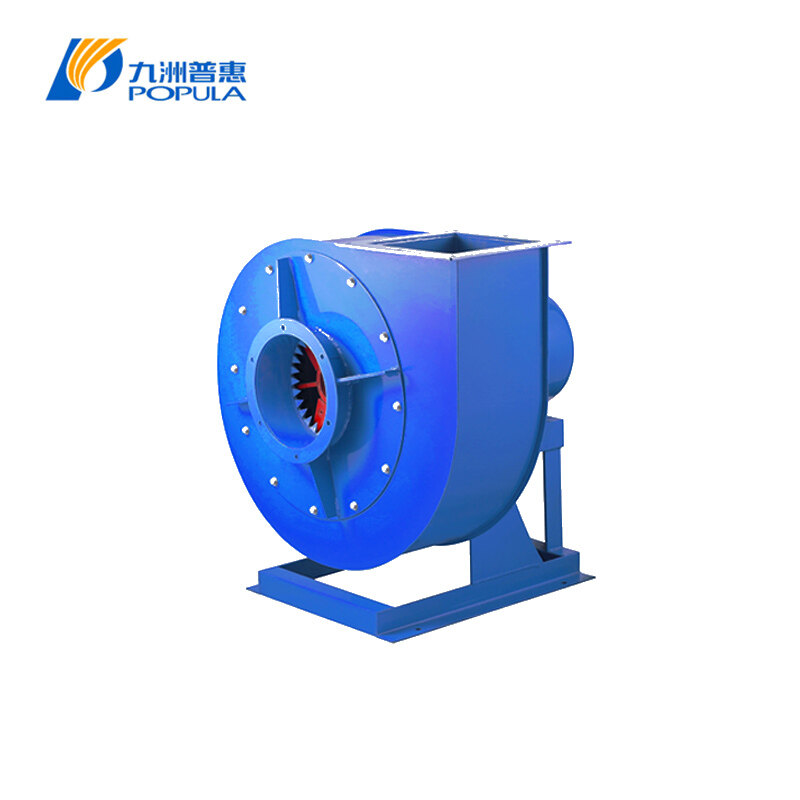

11-62 Model Features:

Material Properties

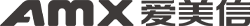

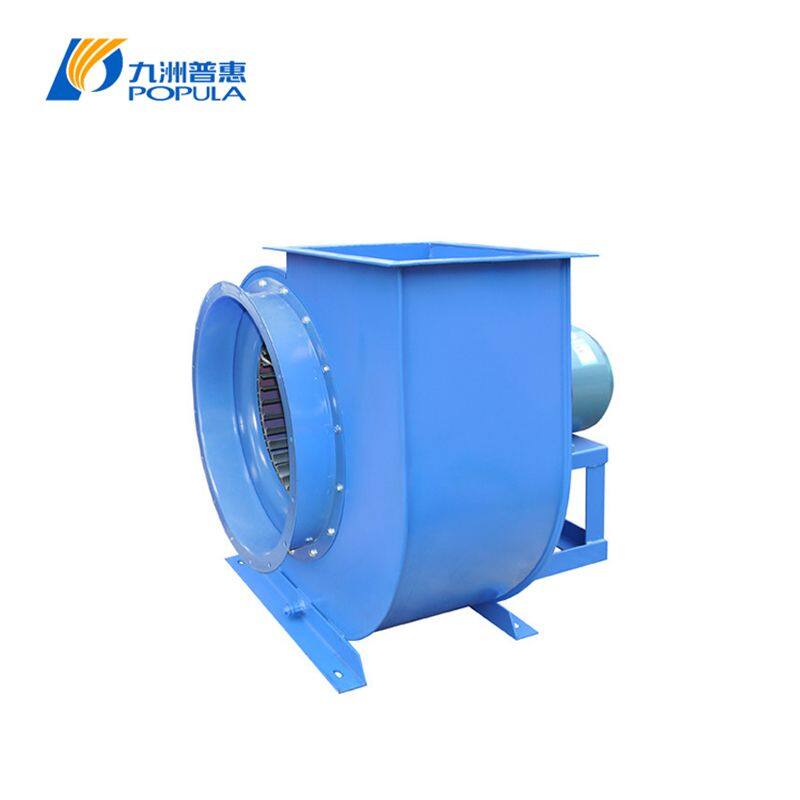

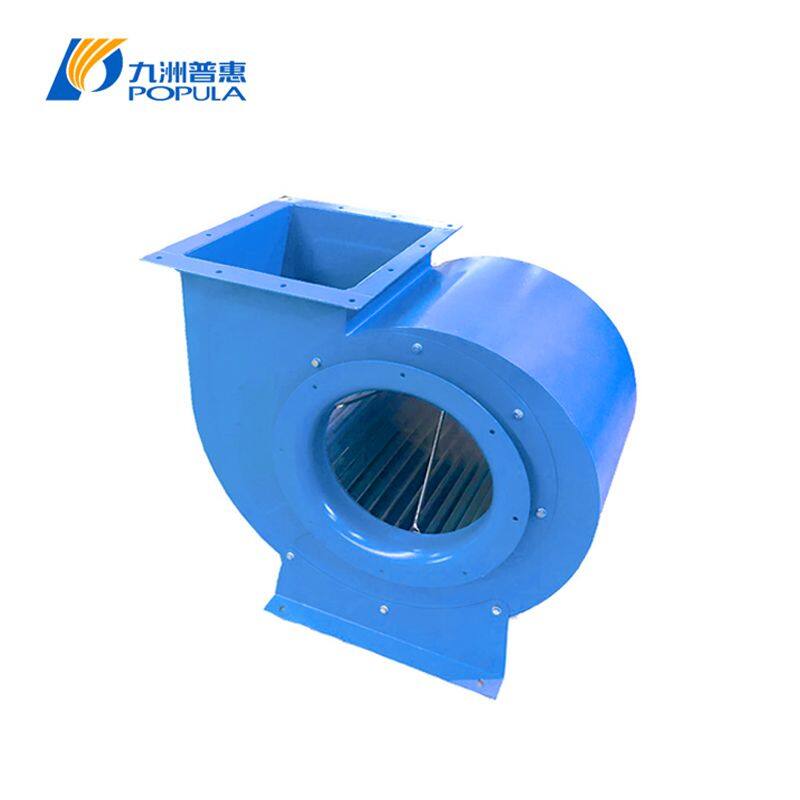

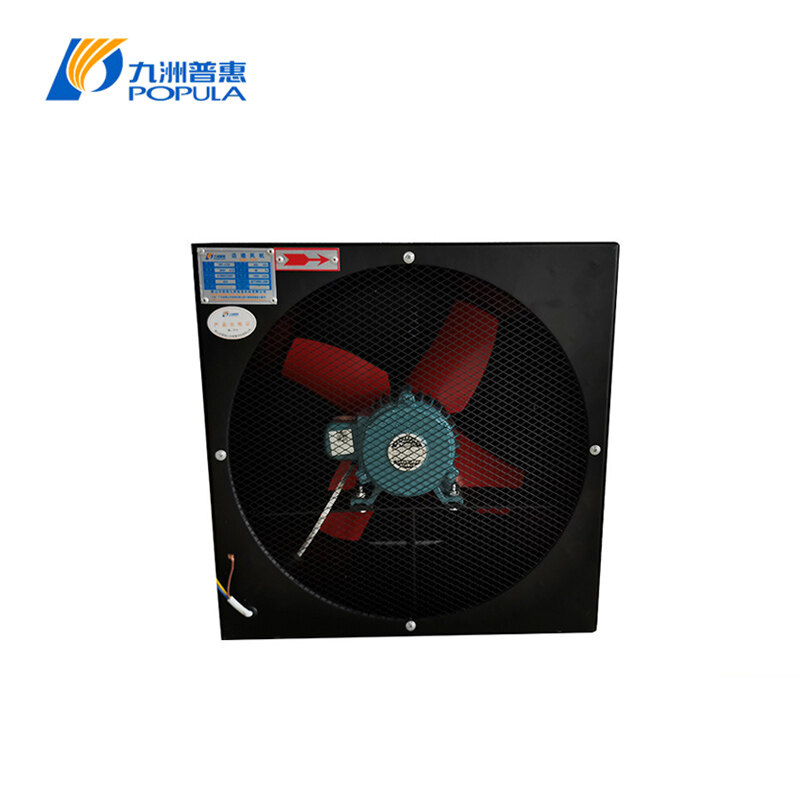

This product is composed of an air inlet, air outlet, impeller, structure, and motor. The impeller is made of a high-quality steel plate; we use 40 to 86 circular arc vanes to build the impeller by welding and testing it with static and dynamic balance correction. It also has the advantage of perfect aerodynamic performance, low noise, and stable operation.

Fan Structure

It is made of a high-quality steel plate, and the worm tongue part of the shell has adapted the newest silencing structure to lower the noise; the shell could be customized to use stainless steel as the material. The transporting medium is air or other non-spontaneous-combustion and non-explosive-combustion air with no harm to humans.

Benefits

The air transferred shall not contain any adhesive material, dust, or grain, and the concentration shall not exceed 150mg/m3, with the temperature no higher than 80℃.

Installation

Install the fan according to the pictures, make sure that the shell is clean inside out, and maintain the balance of the fan while installing it. The contact surface between the fan and the base and the connections between the inlet pipe and the fan should be fixed with each other naturally. Don’t force them; it’s forbidden to transfer the pipe’s weight on the fan and ensure the balance of the fan.

Operating

After the installation and the inspection, we will have a test run, and it should be under no-load condition, by closing all air inlet valves, then turning into full-load according to the operating situation, by opening all air inlet valves; the test run for new fan and the fan after repairing can’t be lessor than 2 hours.

Maintenance

The maintenance can only be done when the fan is stopped to ensure safety. After the maintenance please remember to have a test run first before operating it. And also, remember to clean the dust, dirt, and other impurities regularly. If the fan is using in kitchen or spraying occasion, please clean the impeller every 60 days, otherwise it will cause the overloading of the fan by damage the motor and reduce the air volume.

| Model | Power (KW) |

Voltage (V) |

RPM (r/min) |

Volume(m³/h) | Pressure(Pa ) |

| 2.65A | 0.55 | 220 | 1400 | 1215~2413 | 428~368 |

| 0.55 | 220 | 1400 | 1215~2413 | 428~368 | |

| 2.8A | 0.75 | 220 | 1400 | 1370~2760 | 480~345 |

| 0.75 | 380 | 1400 | 1370~2760 | 480~345 | |

| 3A | 0.75 | 380 | 910 | 1408~2850 | 300~260 |

| 1.5 | 220 | 1420 | 2150~4270 | 654~535 | |

| 1.5 | 380 | 1420 | 2150~4270 | 654~535 | |

| 2.2 | 220 | 1420 | 2200~4400 | 650~520 | |

| 2.2 | 380 | 1420 | 2200~4400 | 650~520 | |

| 3.5A | 1.1 | 380 | 910 | 3200~5080 | 438~367 |

| 3 | 220 | 1420 | 5075~8065 | 1000~840 | |

| 3 | 380 | 1420 | 5075~8065 | 1000~840 | |

| 2.2 | 220 | 1420 | 2365~5613 | 702~767 | |

| 2.2 | 380 | 1420 | 2365~5613 | 702~767 | |

| 4A | 2.2 | 380 | 960 | 4860~7807 | 684~586 |

| 3 | 380 | 960 | 5742~8830 | 670~520 | |

| 4.5A | 3 | 380 | 960 | 6175~9220 | 896~837 |

| 4 | 380 | 960 | 7342~11120 | 880~837 | |

| 5A | 4 | 380 | 960 | 8127~10051 | 1167~1090 |

| 5.5 | 380 | 960 | 8857~13021 | 1147~1018 | |

| 6A | 7.5 | 380 | 960 | 9820~16894 | 1200~990 |

| 6.5A | 11 | 380 | 970 | 10800~21000 | 1270~1100 |

| 7A | 11 | 380 | 730 | 12053~21330 | 1080~950 |