In the realm of airflow management, small centrifugal blower fans stand out as versatile and efficient devices. These fans are engineered with precision to handle various air-handling tasks in compact environments.

Definition and Function

Overview of Centrifugal Blower Technology

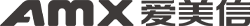

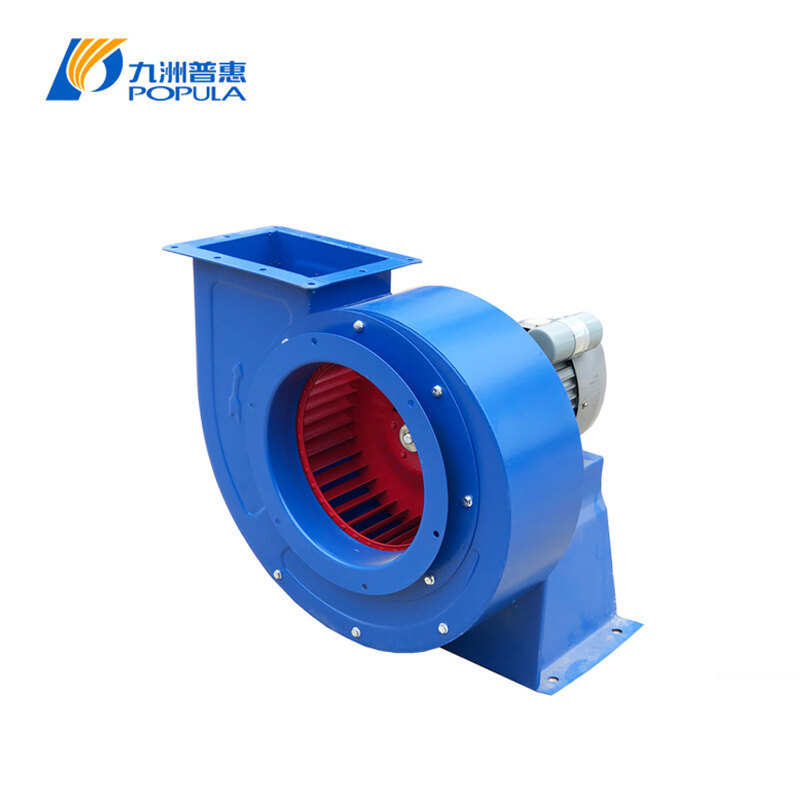

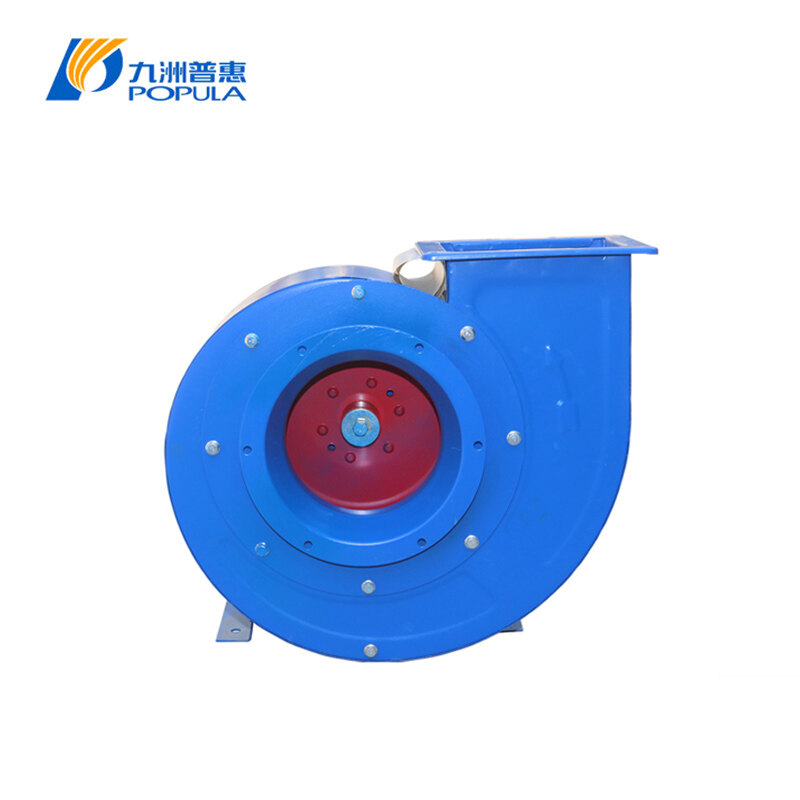

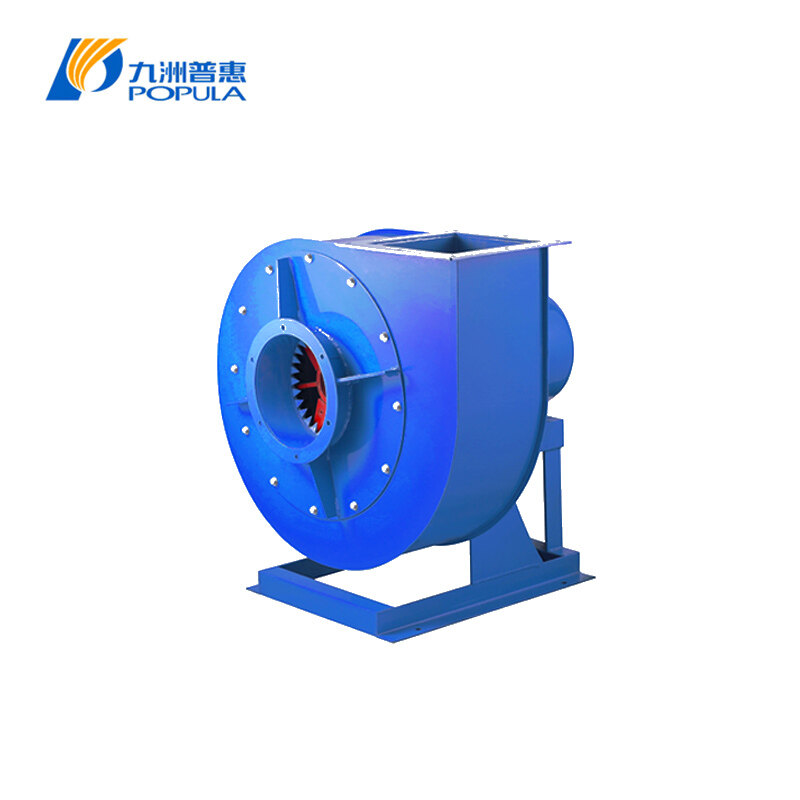

Unlike traditional axial fans, centrifugal blowers utilize a rotating impeller to generate airflow perpendicular to the fan's intake. This design enables efficient air compression and directional control, making them ideal for applications requiring higher pressures.

Importance of Small-Scale Applications

Small centrifugal blower fans play a crucial role in environments where space is limited, offering effective airflow solutions without compromising performance.

Advantages of Small Centrifugal Blower Fans

Efficient Airflow Management

Enhanced Pressure Generation: Small centrifugal blowers excel in generating higher pressures compared to axial fans, making them suitable for applications requiring air to be moved against resistance, such as ductwork or filters.

Precise Air Direction Control: The design of centrifugal blowers allows for precise control over the direction of airflow, enabling targeted ventilation or cooling in confined spaces with minimal turbulence.

Compact Design and Versatility

Space-Saving Solutions: With their compact form factor, small centrifugal blower fans are well-suited for installations where space is at a premium, offering efficient airflow management without occupying excessive room.

Adaptability to Various Environments: These fans are designed to operate reliably in diverse environments, from HVAC systems in residential and commercial buildings to industrial processes requiring robust air-handling capabilities.

Applications and Industries

HVAC Systems

Ventilation and Air Conditioning: Small centrifugal blowers are integral components of HVAC systems, facilitating the circulation of conditioned air throughout buildings and ensuring consistent comfort levels for occupants.

Heating and Cooling Applications: In heating and cooling systems, these fans assist in distributing air evenly across heat exchangers or evaporator coils, optimizing thermal transfer efficiency for enhanced performance.

Industrial Processes

Air Filtration and Dust Collection: industries rely on small centrifugal blower fans for air filtration and dust collection applications, where they create negative pressure environments to extract contaminants from workspaces and maintain air quality standards.

Material Conveying and Drying Processes: Small centrifugal blowers are also utilized in material conveying and drying processes, providing the necessary airflow for transporting bulk materials or accelerating drying times in production environments.

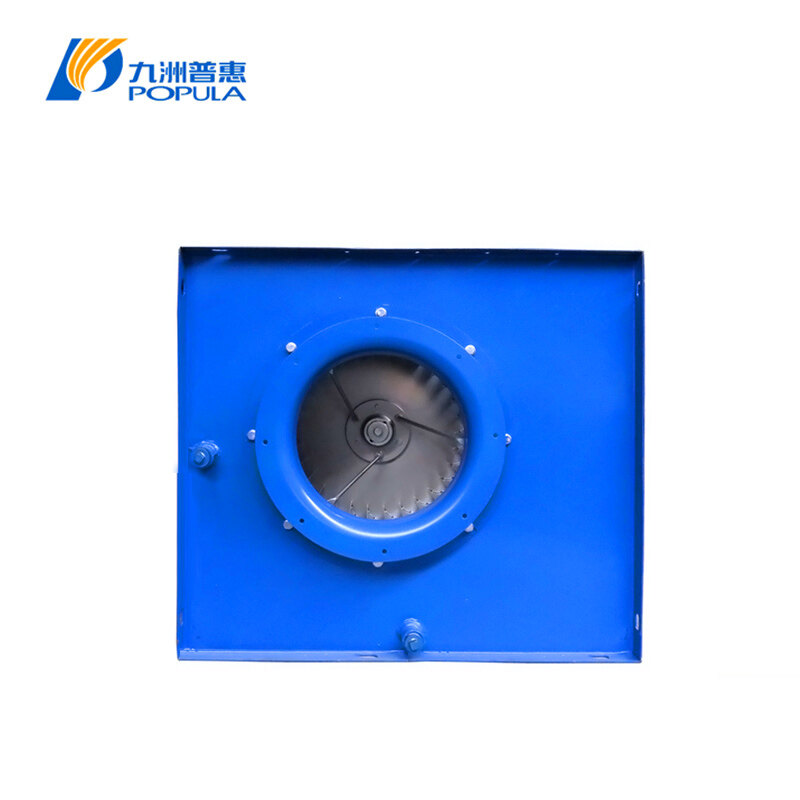

Small Low Noise Centrifugal Fan

Considerations for Selecting Small Centrifugal Blower Fans

Airflow Requirements

CFM (Cubic Feet per Minute) Specifications: Determining the required airflow volume is essential when selecting a small centrifugal blower fan, ensuring it meets the demands of the application without over- or underperforming.

Static Pressure Considerations: Static pressure, or the resistance to airflow within a system, must be accounted for to ensure the fan can overcome any obstacles or ductwork restrictions encountered during operation.

Size and Installation

Matching Fan Size to Application: Properly sizing the fan relative to the application's airflow requirements is crucial for optimal performance and energy efficiency, avoiding issues such as airflow inadequacy or excessive noise.

Proper Mounting and Ducting Arrangements: Correct installation, including appropriate mounting and ducting arrangements, is essential for maximizing the fan's effectiveness and minimizing air leakage or turbulence within the system.

Conclusion

Small centrifugal blower fans represent a sophisticated solution for efficient airflow management in various applications and industries. Their compact design, enhanced pressure generation capabilities, and adaptability make them indispensable components of HVAC systems and industrial processes alike.

By considering factors such as airflow requirements, static pressure considerations, and proper installation practices, businesses and homeowners can harness the full potential of these versatile air-handling devices to meet their specific needs and challenges.