When it comes to plasma cutting operations, efficient fume extraction is crucial for maintaining a safe and productive work environment. A high-quality plasma table exhaust fan plays a vital role in removing harmful fumes and particulates generated during the cutting process. In this comprehensive guide, we'll explore the essential features to consider when selecting a plasma table exhaust fan for your manufacturing facility.

Understanding the Importance of Plasma Table Exhaust Fans

Plasma cutting is a widely used technique in metal fabrication, known for its precision and efficiency. However, this process generates a significant amount of smoke, dust, and potentially hazardous fumes. A properly designed plasma table exhaust fan is essential for the following:

* Protecting worker health and safety

* Maintaining air quality in the workspace

* Enhancing visibility during cutting operations

* Prolonging the life of equipment by reducing contamination

Key Features to Look for in a Plasma Table Exhaust Fan

1. Powerful Airflow Capacity

The primary function of a plasma table exhaust fan is to effectively remove fumes and particulates. Look for fans with high cubic feet per minute (CFM) ratings that match or exceed your plasma table's requirements. A powerful fan ensures thorough fume extraction, even during heavy-duty cutting operations.

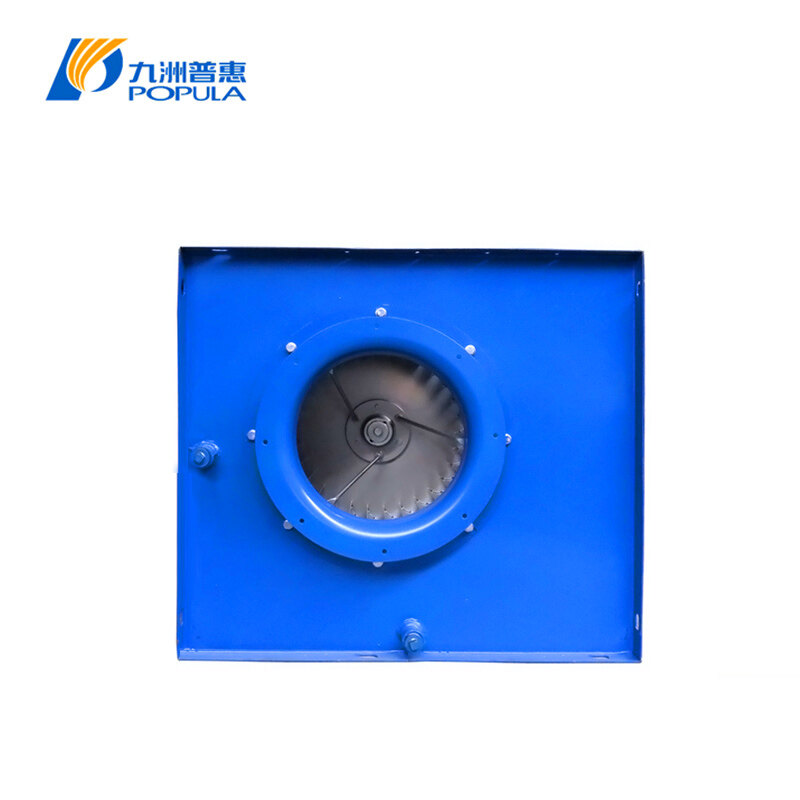

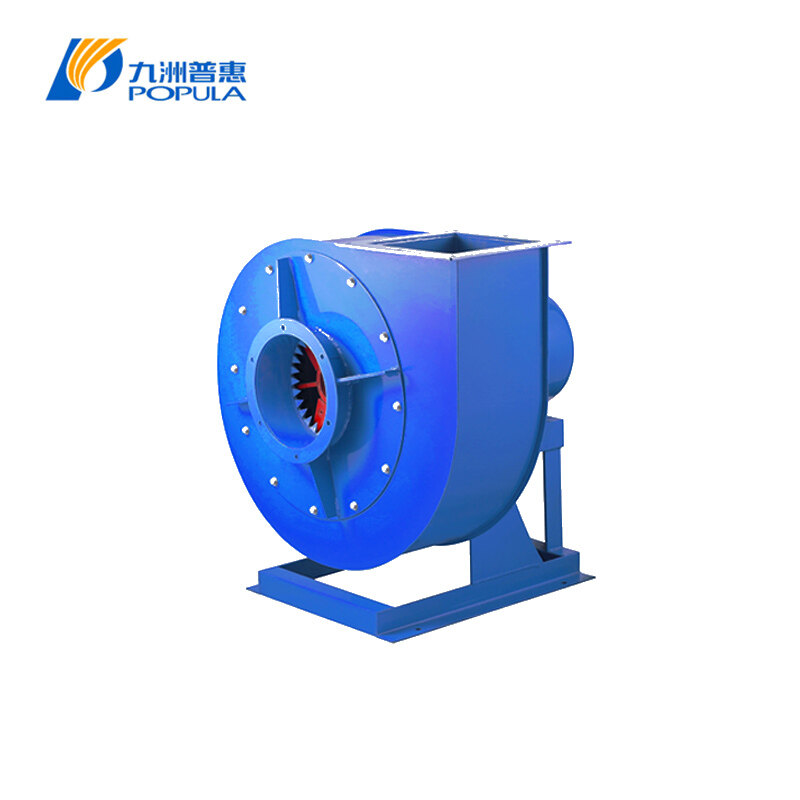

2. Durable Construction

Plasma cutting environments can be harsh, with exposure to heat, metal particles, and corrosive fumes. Choose a plasma table exhaust fan constructed from robust materials such as:

* Stainless steel housing for corrosion resistance

* High-grade aluminum impellers for durability and efficiency

* Industrial-grade motors designed for continuous operation

3. Efficient Filtration System

An effective filtration system is crucial for capturing fine particles and maintaining air quality. Look for fans equipped with:

* HEPA filters for capturing submicron particles

* Activated carbon filters for absorbing odors and gases

* Easy-to-replace filter cartridges for simplified maintenance

4. Variable Speed Control

Different cutting operations may require varying levels of exhaust. A plasma table exhaust fan with variable speed control allows you to adjust airflow based on specific cutting requirements, optimizing energy efficiency and noise levels.

5. Low Noise Operation

While powerful airflow is essential, it shouldn't come at the cost of excessive noise. Look for fans designed with noise reduction features such as:

* Aerodynamically optimized impellers

* Sound-dampening materials in the fan housing

* Vibration isolation mounts

6. Smart Monitoring and Control Systems

Modern plasma table exhaust fans often come equipped with intelligent features that enhance performance and ease of use:

* Digital control panels for precise airflow adjustment

* Real-time filter status monitoring

* Automatic startup and shutdown synchronized with plasma table operation

7. Compact and Flexible Design

Space efficiency is often a concern in manufacturing environments. Choose a fan that:

* Has a compact footprint to minimize floor space requirements

* Offers flexible mounting options (floor, wall, or ceiling)

* Provides easy access for maintenance and filter changes

8. Energy Efficiency

Look for fans with energy-efficient motors and smart control systems that optimize power consumption without compromising performance. This not only reduces operating costs but also aligns with sustainable manufacturing practices.

9. Compliance with Safety Standards

Ensure that the plasma table exhaust fan you choose meets or exceeds relevant safety and environmental standards, such as:

* OSHA regulations for air quality in the workplace

* EPA guidelines for emissions control

* UL certifications for electrical safety

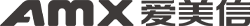

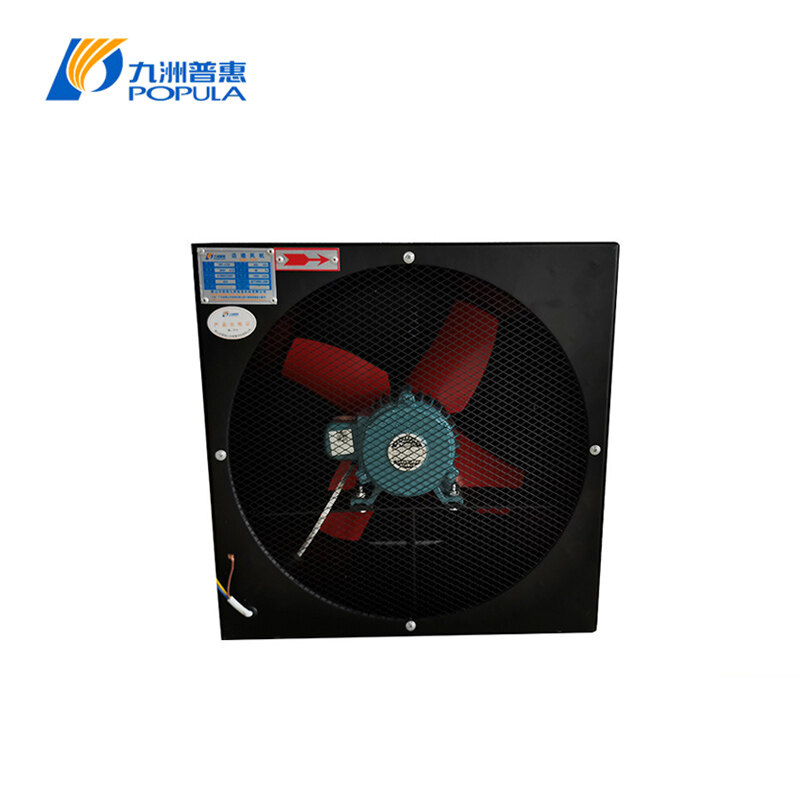

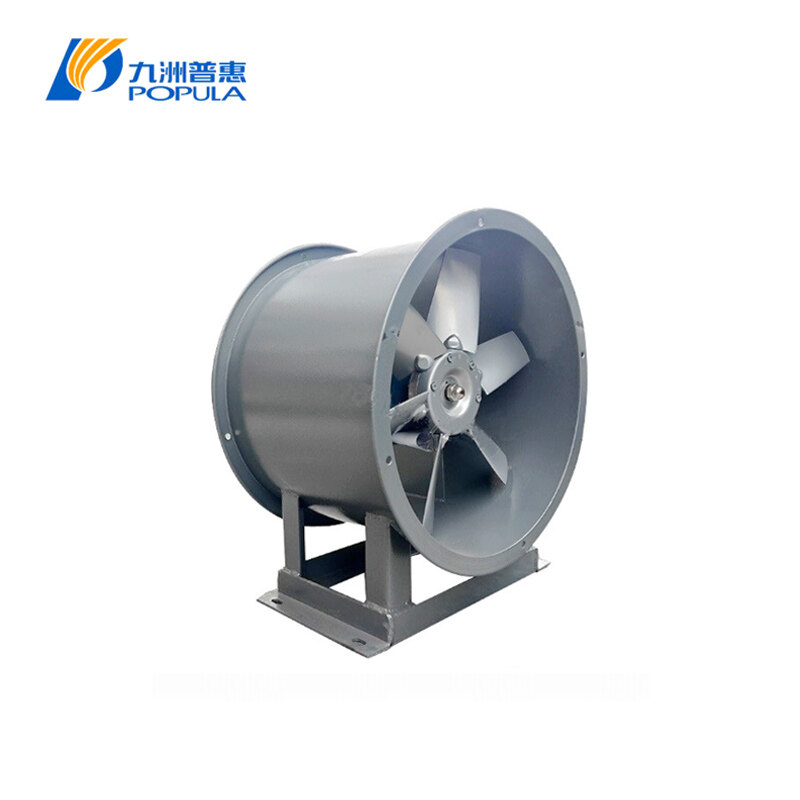

Introducing AMX's High-Quality Exhaust Fan Solutions

When it comes to reliable and efficient plasma table exhaust fans, AMX offers cutting-edge solutions designed to meet the demanding requirements of modern manufacturing facilities. Our high-quality exhaust fans are engineered with precision to deliver optimal performance in plasma cutting environments.

Key features of AMX exhaust fans include:

* Robust construction for durability in harsh conditions

* High-efficiency motors for powerful airflow and energy savings

* Advanced filtration systems for superior air quality

* User-friendly controls for easy operation and maintenance

* Compact designs that maximize workspace efficiency

By choosing an AMX exhaust fan for your plasma table, you're investing in a solution that not only enhances workplace safety but also contributes to improved productivity and operational efficiency.

Conclusion

Selecting the right plasma table exhaust fan is crucial for maintaining a safe, efficient, and productive cutting environment. By focusing on key features such as powerful airflow, durable construction, efficient filtration, and smart control systems, you can ensure that your plasma cutting operations are supported by top-notch fume extraction technology.

Remember, investing in a high-quality exhaust fan is not just about compliance with safety regulations—it's about creating a better work environment that promotes productivity, protects worker health, and contributes to the longevity of your equipment. Take the time to assess your specific needs and choose a plasma table exhaust fan that will serve your facility well for years to come.