In today's ever-changing industrial landscape, maintaining optimal air quality and ventilation is paramount for both employee well-being and operational efficiency. Among the myriad ventilation solutions available, one stands out as a powerful and reliable option - the industrial centrifugal extractor fan. In this comprehensive article, we'll explore why they are favored over other ventilation systems and how they can make a significant impact across various industries.

Industrial Centrifugal Extractor Fan: Understanding the Basics

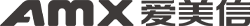

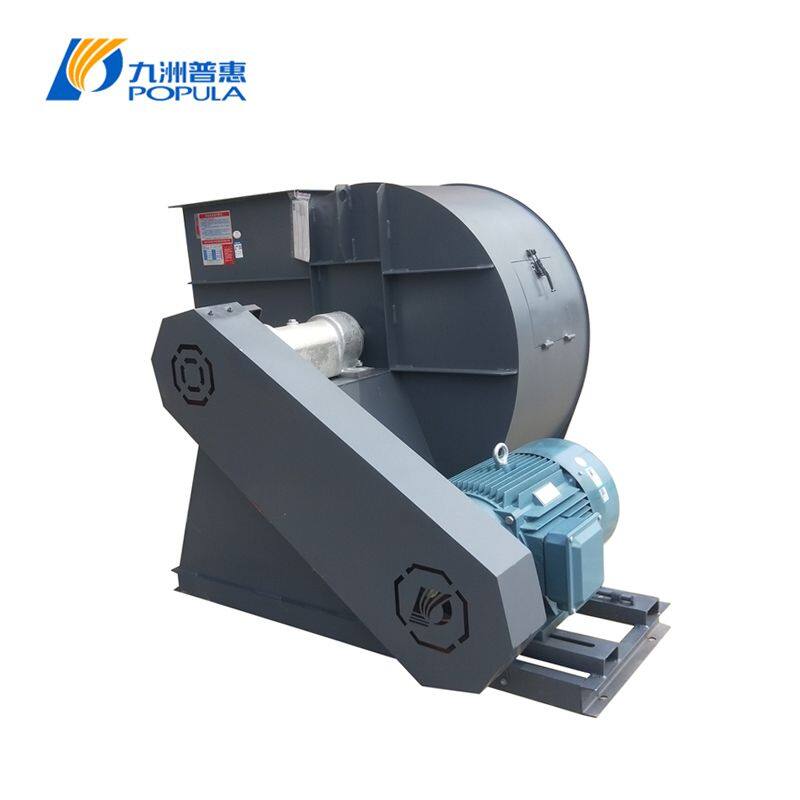

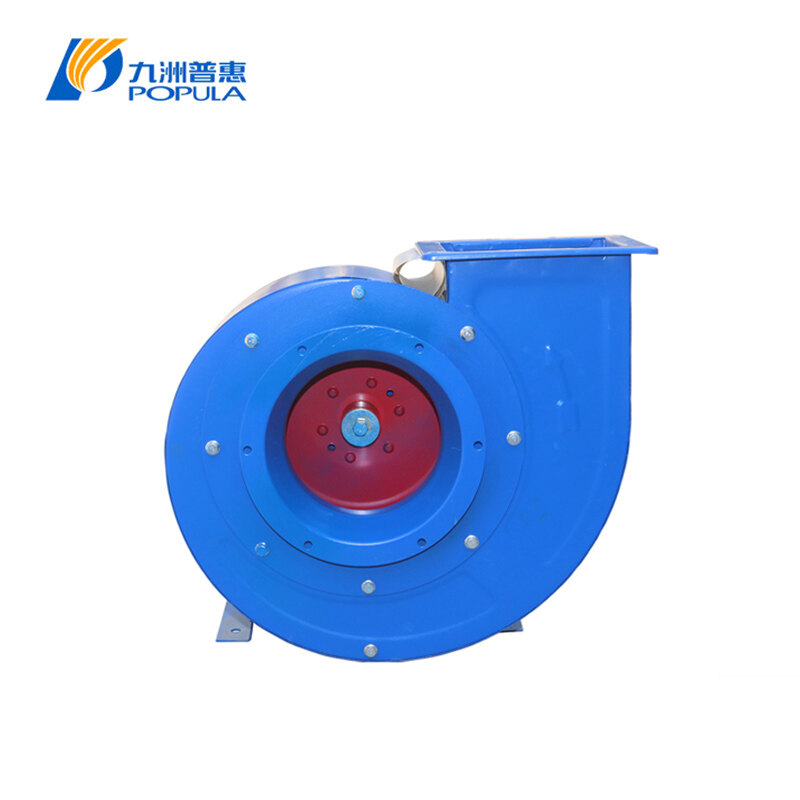

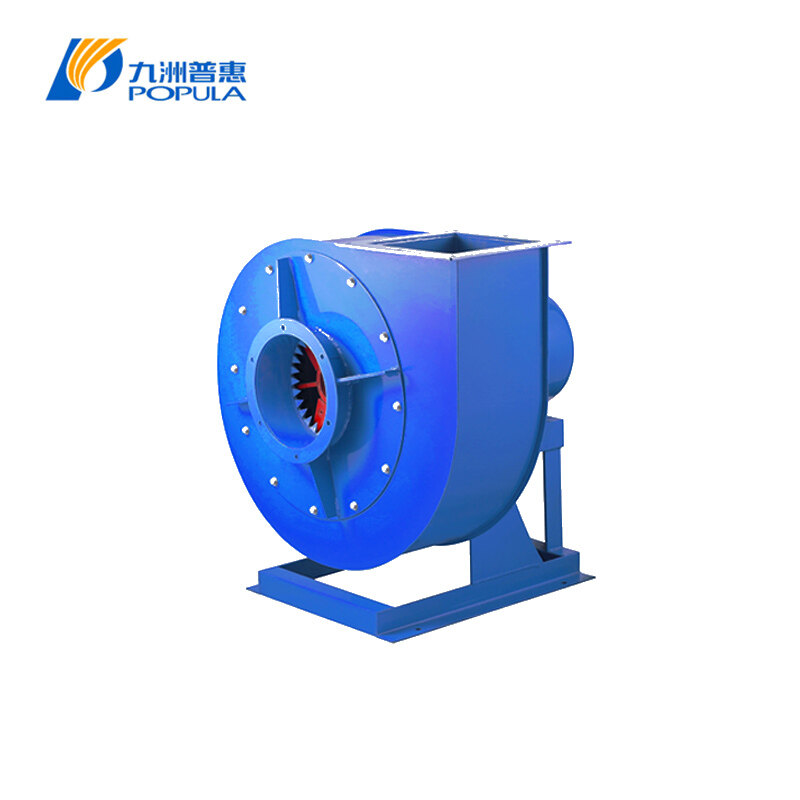

Before delving into the specifics, let's grasp the fundamentals of industrial centrifugal extractor fans. As a part of the larger family of centrifugal fans, it operates based on the principle of rotating impellers that increase the air's velocity before discharge. Unlike axial fans that move air parallel to the fan's axis, centrifugal fans direct airflow perpendicular to the impeller's rotation. This design variation allows industrial centrifugal extractor fans to generate higher static pressures, making them ideal for applications that require enhanced airflow against resistance.

Benefits of Industrial Centrifugal Extractor Fans

Industrial centrifugal extractor fans offer a plethora of advantages that set them apart from other ventilation solutions. Here are some key advantages of it.

Higher Efficiency But Lower Energy Consumption: Thanks to their innovative design, these fans can move large volumes of air with lower energy consumption, leading to cost savings and reduced environmental impact.

Enhanced Airflow against Resistance: Industrial settings often feature obstacles or duct systems that resist the airflow. Centrifugal fans excel in handling such resistance, maintaining consistent airflow and ventilation.

Improved Air Quality: By efficiently circulating fresh air and removing stale air, dust, and pollutants, industrial centrifugal extractor fans create a healthier and safer work environment.

Versatility in Applications: From manufacturing facilities and warehouses to commercial kitchens and laboratories, industrial centrifugal extractor fans find applications in diverse industries due to their adaptability.

Noise Reduction: With advanced engineering and robust construction, centrifugal extractor fans produce less noise, ensuring a quieter work environment for employees.

Durability and Longevity: Designed to withstand harsh conditions, industrial centrifugal extractor fans are known for their durability and extended operational life, providing a reliable ventilation solution.

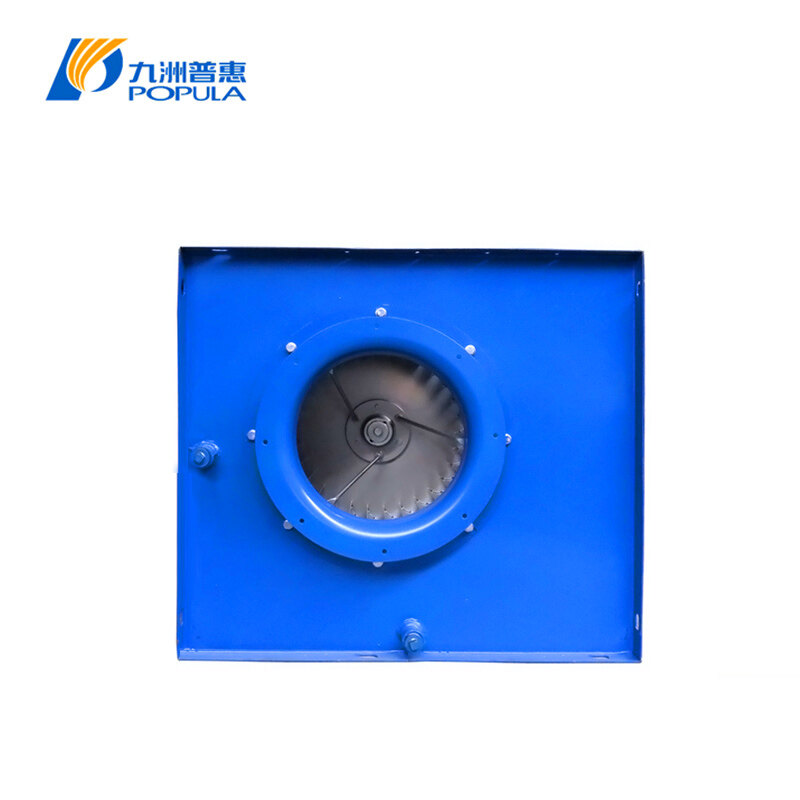

industrial centrifugal extractor fan

Factors Influencing Industrial Centrifugal Extractor Fan Selection

Airflow Requirements

Determining the required airflow volume is crucial as it directly impacts the fan's size and power. Factors such as the size of the space, the number of employees, and the equipment present influence the airflow requirements.

Static Pressure

Static pressure is the resistance the fan must overcome to ensure adequate air circulation. Accurate calculation of the system's static pressure is essential to select a fan with the appropriate capability.

Fan Size and Configuration

Industrial centrifugal extractor fans come in various sizes and configurations. Selecting the right size and type ensures optimal performance and efficient ventilation.

Noise Levels

In noise-sensitive environments, choosing a fan with lower noise levels is imperative to maintain a conducive workspace for employees.

Energy Efficiency

Opting for energy-efficient fans not only reduces operational costs but also aligns with sustainability goals and environmental considerations.

Material and Construction

The choice of materials and construction impacts the fan's durability and its ability to withstand the harsh conditions prevalent in industrial environments.

Industrial Centrifugal Extractor Fan Applications

Manufacturing Industries: From automotive plants to electronics manufacturing facilities, these fans ensure proper ventilation and contribute to efficient production processes.

Warehouses and Distribution Centers: Maintaining good air quality is vital in these large spaces to safeguard employee health and protect stored goods.

Commercial Kitchens: Industrial centrifugal extractor fans effectively remove cooking fumes, steam, and odors from commercial kitchens, ensuring a comfortable and safe environment for chefs and staff.

Laboratories and Cleanrooms: These controlled environments require precise ventilation to prevent contamination, and centrifugal fans deliver the necessary airflow without compromising sterility.

HVAC Systems: Centrifugal fans play a crucial role in HVAC systems, efficiently distributing conditioned air throughout buildings and facilities.

Mining and Construction: In dusty and hazardous environments, these fans aid in maintaining air quality and providing a safe workspace for workers.

Conclusion: A Breath of Fresh Air

Industrial centrifugal extractor fans have revolutionized the way industries approach ventilation and air quality. Their ability to circulate air efficiently, remove pollutants, and maintain a safe work environment makes them indispensable in various applications. Whether it's enhancing productivity in manufacturing or ensuring a comfortable atmosphere in commercial spaces, these fans continue to be a driving force behind cleaner, healthier, and more efficient industrial settings.