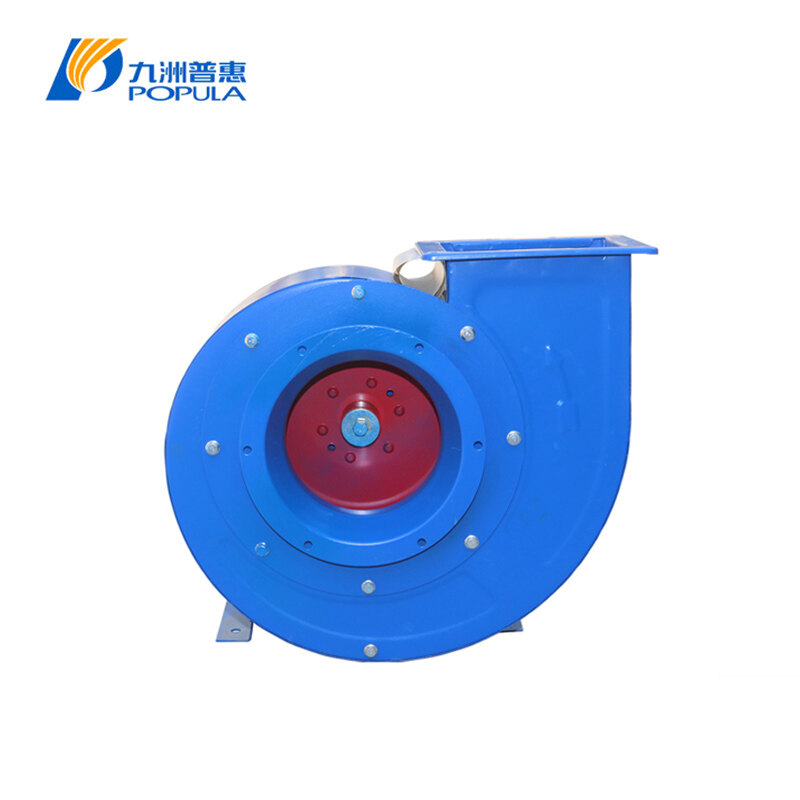

In the centrifugal fan, the impeller, as an essential part, directly affects the efficiency of the centrifugal fan. Its geometry, size, number of blades, and manufacturing accuracy have a great influence on performance.

The impeller can be calibrated by static or dynamic balance to ensure smooth rotation of the fan. According to the different directions of the blade outlet, the impeller is divided into three types: forward, radial and backward.

- The top of the blade of the forward impeller is inclined to the direction of rotation of the impeller.

- The top of the blade of the radial impeller is radial, divided into straight blades and curved blades.

- The top of the blade of the backward impeller is inclined in the opposite direction of the rotation of the impeller.

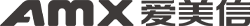

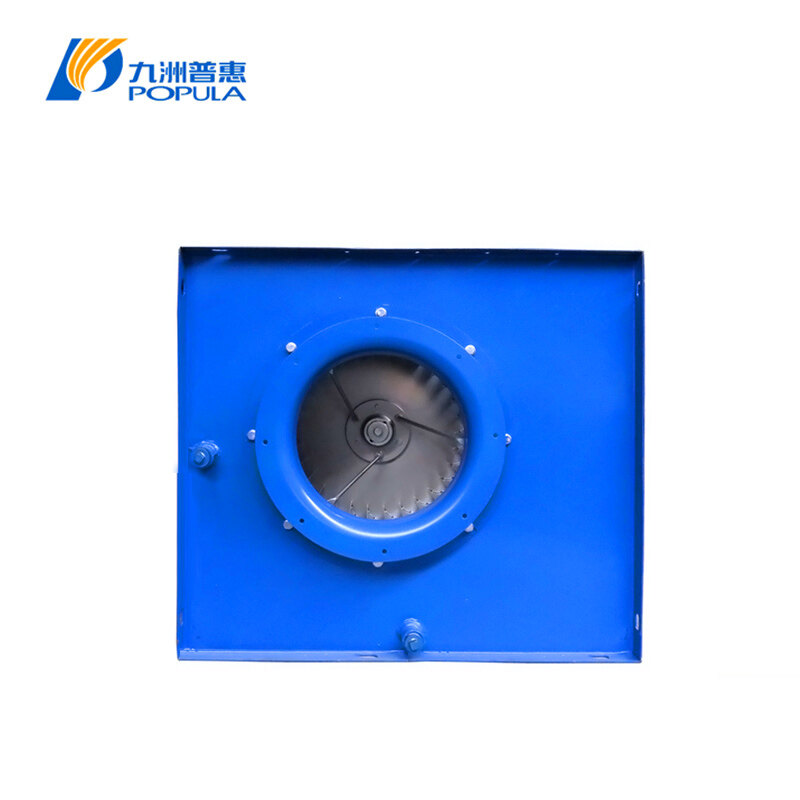

Forward Bladed Centrifugal Fans

Centrifugal fan is a common type of fan in modern society. Everyone knows that fan plays the role of ventilation in daily life. It is of great significance to people's production and life. Therefore, it is a component that people cannot ignore. Under the circumstances, the common centrifugal fan is mainly composed of the impeller and the casing. Due to the different installation positions, there are also different models, but the basic principles are the same.

The general machine needs to be repaired and cleaned after a period of use, which is very troublesome to clean up. Still, the maintenance and cleaning of the centrifugal fan are very convenient because some models of the centrifugal fan are equipped with a cleaning door, so you don't need to disassemble the machine when maintenance, saving time.

The ventilation effect of the centrifugal fan is also very good, and it is especially suitable for pipe extraction or air supply. Moreover, the impeller of the centrifugal fan is reasonably designed to be backward, there is no friction during operation, and the noise is very low and difficult. Contaminated with dust, maintenance is very convenient.

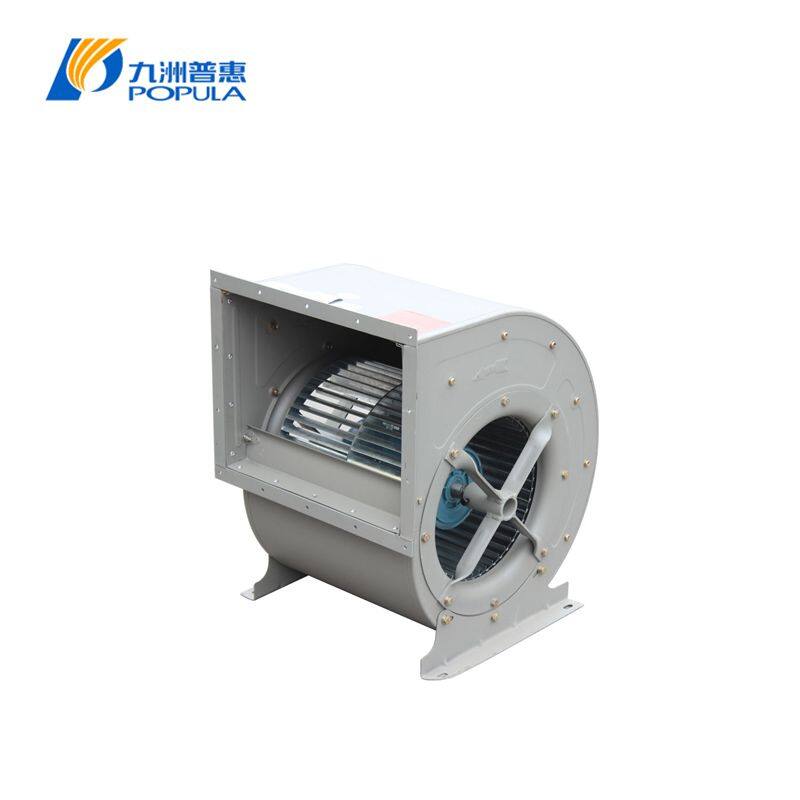

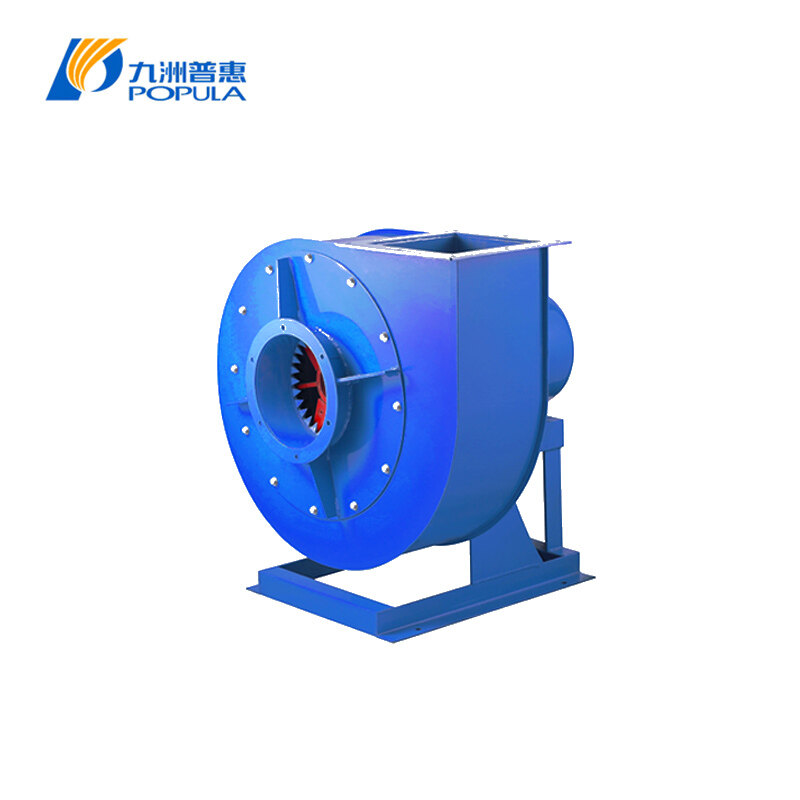

Industrial Centrifugal Blower Fan

The most satisfying thing is that the surface of the centrifugal fan is sprayed, which is resistant to oxidation and is not easy to be rusted. The high-quality steel plate used for the casing and impeller makes the centrifugal fan very strong and durable. In addition, the scope of application of the centrifugal fan is very wide. It can be used in pipelines to transport air and can be used in places where there is no corrosion, flammable and explosive gas.

The centrifugal fan can be made into two types, right-handed and left-handed. Looking from the side of the motor, the impeller rotates clockwise, which is called the right rotating fan, and the impeller rotates counterclockwise, which is called the left rotating fan. A small centrifugal fan is essentially a variable flow and constant pressure device. When the speed is constant, the pressure-flow theoretical curve of the centrifugal fan should be a straight line. Due to internal losses, the actual characteristic curve is curved.

The pressure generated in the centrifugal fan is affected by the greater influence of changes in intake air temperature or density. For a given intake air volume, the highest intake air temperature (the lowest air density) produces the lowest pressure. For a given pressure and flow characteristic curve, there is a power And flow characteristic curve. When the blower is running at a constant speed for a given flow rate, the required power increases with the decrease in the intake air temperature.