Centrifugal fans play a pivotal role in maintaining air quality, particularly in industrial settings where dust particles can be a persistent issue. Understanding the nuances of these fans and their specific application in dust removal is crucial for businesses prioritizing a clean and healthy working environment.

Working Mechanism of Dust Removal Centrifugal Fans

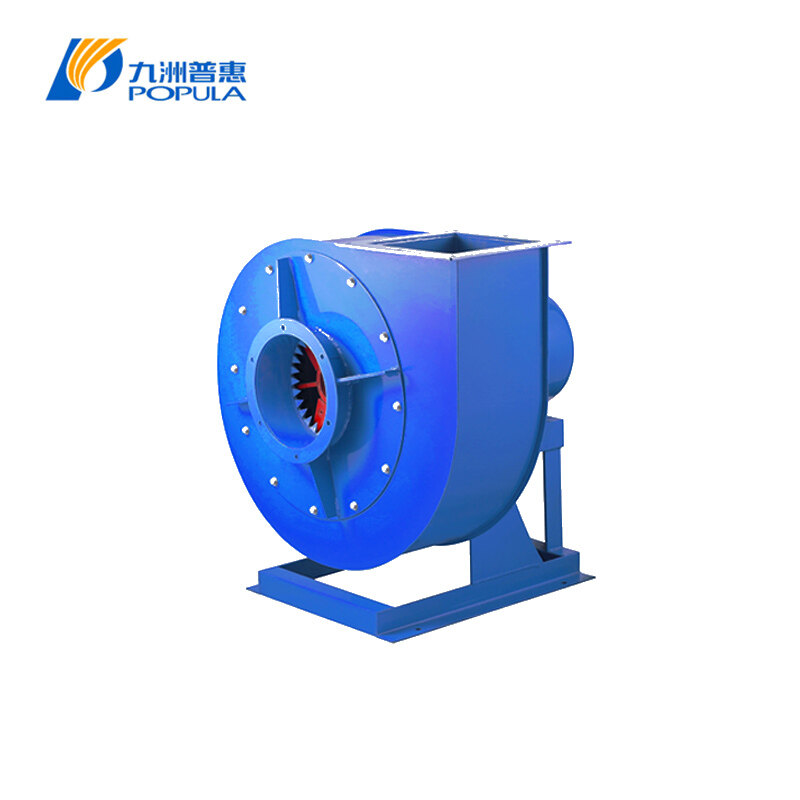

Centrifugal Force in Action

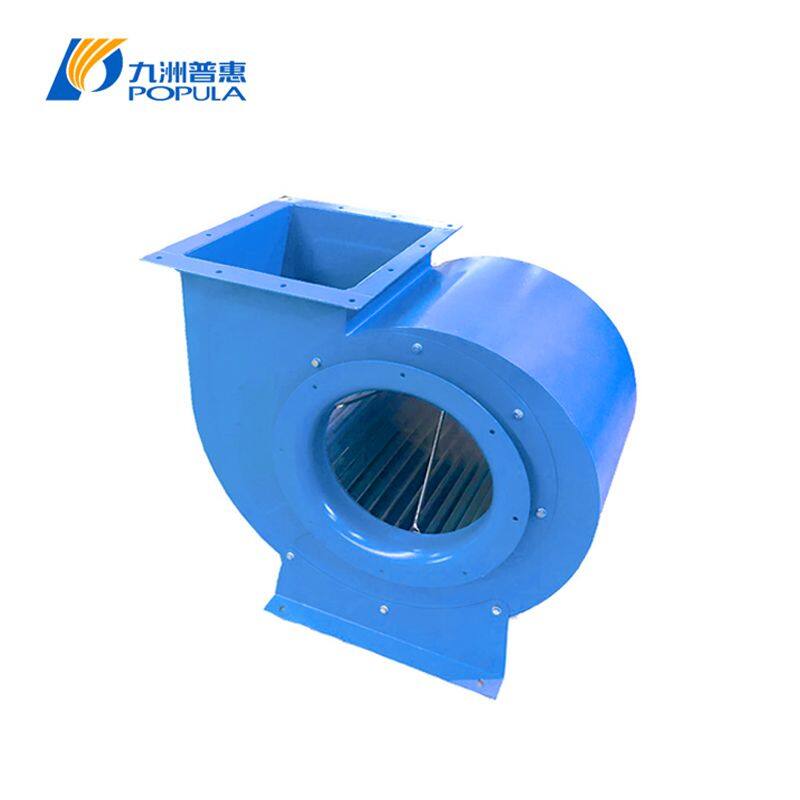

In the realm of physics, centrifugal force takes center stage when it comes to the efficacy of dust removal centrifugal fans. These devices leverage the principles of centrifugation, forcing particles away from the airflow and into designated collection chambers. The intricate dance of air molecules within the fan creates a powerful force field, effectively separating dust from the ambient air.

The efficiency of this process relies on the precise engineering of the fan's impeller.

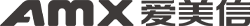

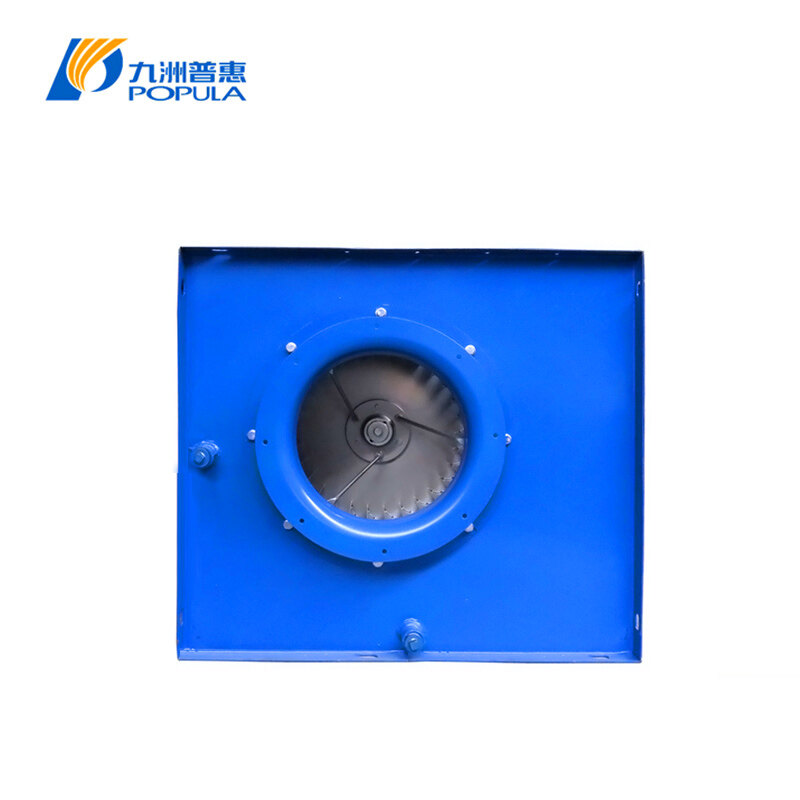

Impeller Design

At the heart of a dust removal centrifugal fan lies its impeller, a carefully crafted component designed for optimal performance. The curvature of the impeller blades is not merely an aesthetic consideration; it's a critical factor determining the fan's ability to generate the necessary centrifugal force. The ingenious design ensures that the airflow is not only forceful but also directed with precision, enhancing the fan's dust-extracting prowess.

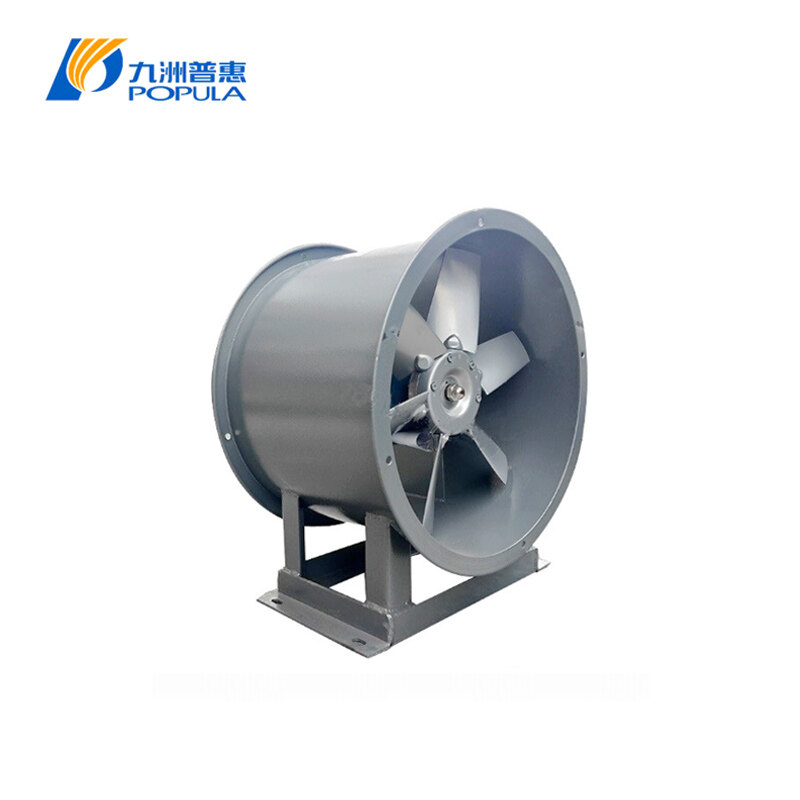

Applications in Various Industries

Industrial Settings

The impact of dust removal centrifugal fans reverberates through various industries, especially manufacturing. These fans become indispensable in environments where dust can compromise both product quality and worker health. By swiftly and effectively extracting dust particles, these fans contribute to the seamless operation of machinery and the overall safety of the manufacturing process.

Environmental Considerations

Beyond industrial applications, dust removal centrifugal fans play a crucial role in environmental stewardship. As industries grapple with the responsibility of minimizing their ecological footprint, these fans emerge as silent guardians of air quality. Whether it's a factory floor or a laboratory, the deployment of these fans ensures that the air we breathe remains free from harmful particulate matter, fostering a healthier and more sustainable workplace.

Choosing the Right Dust Removal Centrifugal Fan

Size and Capacity

Selecting the appropriate size and capacity is paramount when integrating dust removal centrifugal fans into a system. A miscalculation can lead to inefficiencies or, worse, inadequate dust removal. Understanding the unique requirements of the environment, including factors like square footage and the nature of dust particles, guides the selection process. A harmonious match between the fan's capacity and the dust removal demands ensures optimal performance.

Material and Durability

The construction materials of dust removal centrifugal fans are not to be overlooked. In demanding industrial settings, these fans often operate under harsh conditions. Robust materials ensure durability, preventing premature wear and tear. Stainless steel, for example, not only withstands the rigors of continuous operation but also resists corrosion, prolonging the fan's lifespan and maintaining its efficiency.

Conclusion

The dust removal centrifugal fan represents a technological marvel, seamlessly blending physics and engineering to address the perennial issue of dust in various environments. From industrial floors to laboratories, their impact on air quality is profound, underscoring their importance in modern workplaces committed to health, safety, and environmental responsibility.