In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, the efficiency and reliability of air movement are paramount. One of the essential devices in this domain is the cabinet type centrifugal fan. These fans are not just components; they are critical to ensuring optimal air circulation, energy efficiency, and overall system performance.

Understanding Cabinet Type Centrifugal Fans

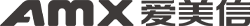

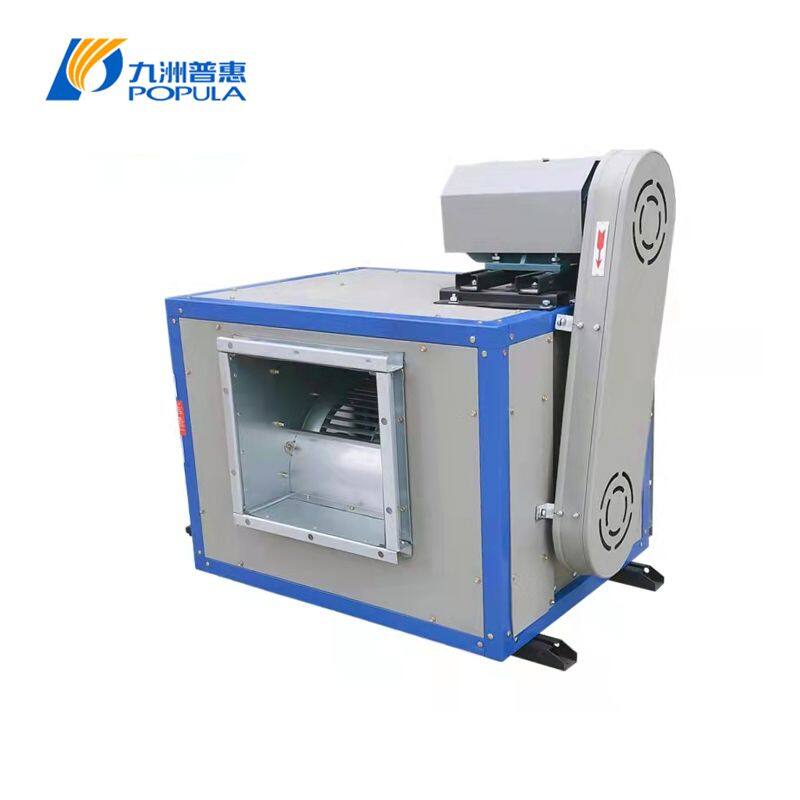

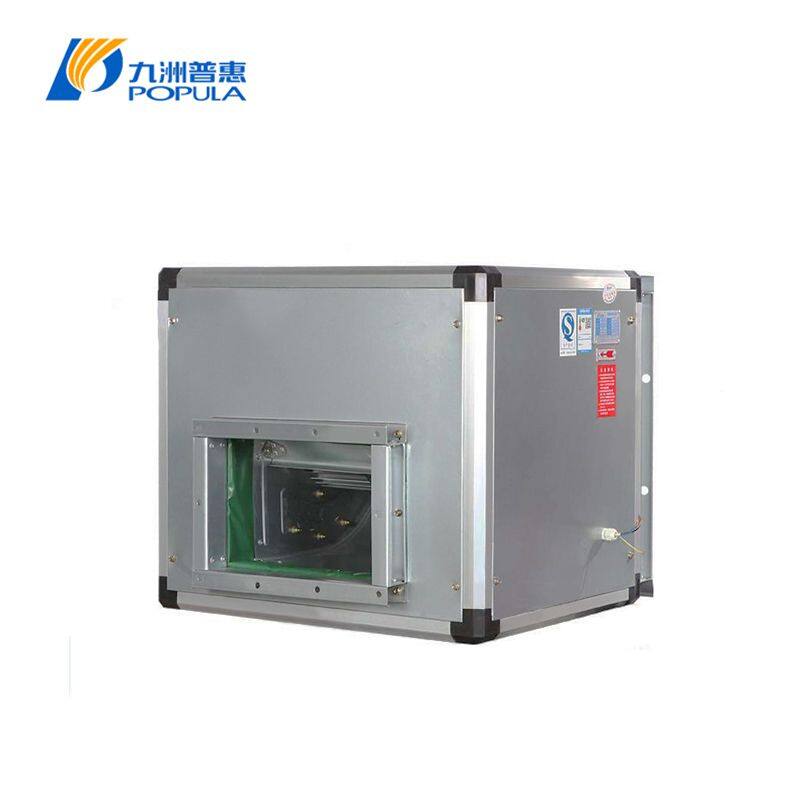

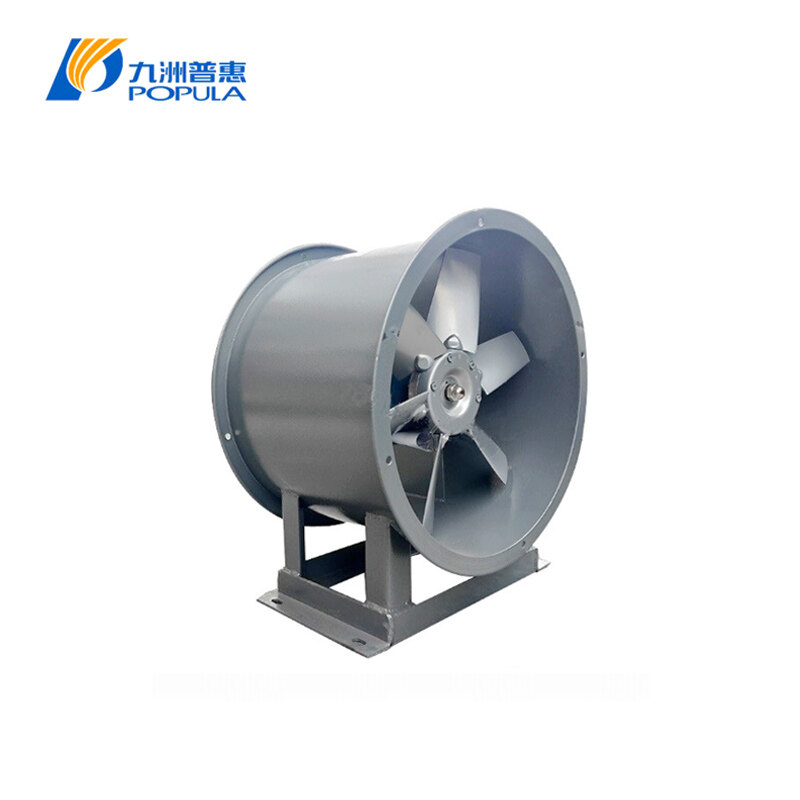

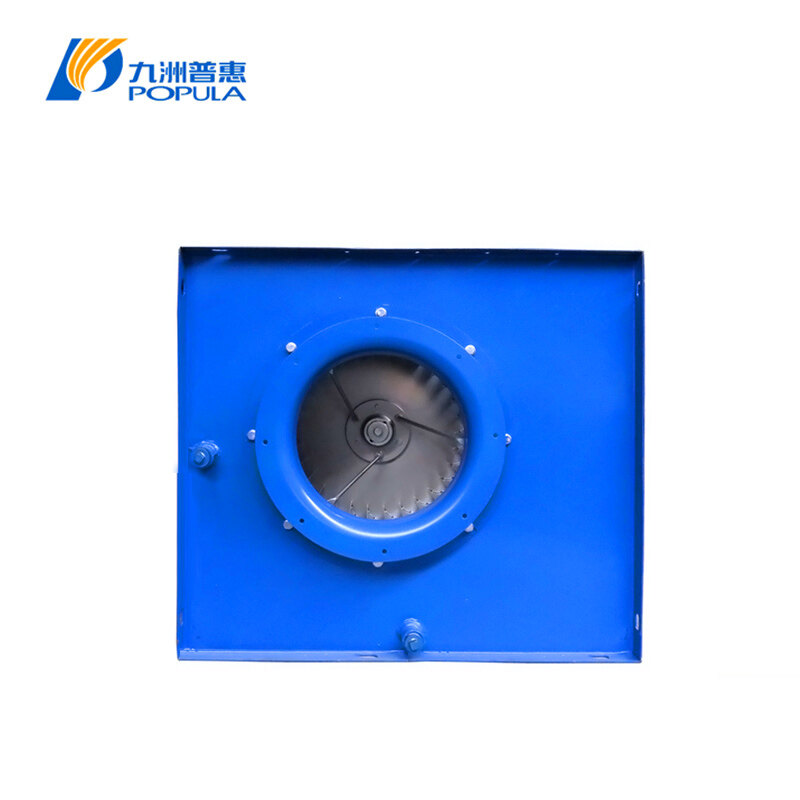

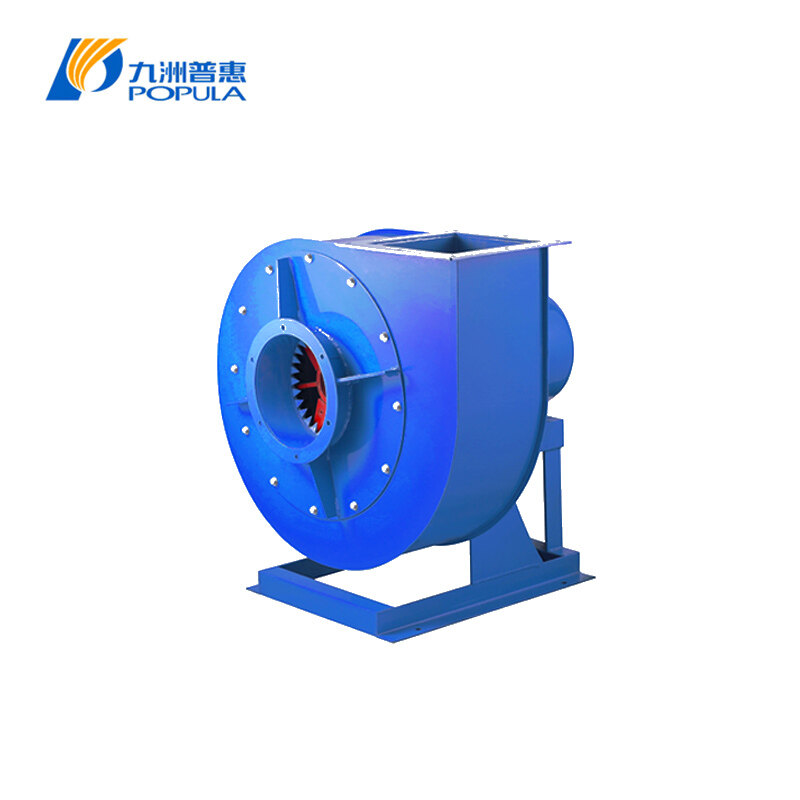

A cabinet type centrifugal fan is designed to move air through a system with minimal resistance, making it ideal for various applications, including industrial and commercial settings. These fans are characterized by their enclosed design, which allows for quieter operation and protection from external elements.

Key Features:

High Efficiency: Cabinet type centrifugal fans are engineered to provide high airflow with low energy consumption, making them a sustainable choice for HVAC systems.

Versatile Applications: These fans can be used in a variety of settings, from large commercial buildings to specialized industrial environments, ensuring that air is distributed evenly and effectively.

Durability and Maintenance: With robust construction, these fans are designed to withstand harsh conditions, requiring less frequent maintenance and offering a longer lifespan.

Big Air Volume Cabinet Centrifugal Fan

Key Benefits of Using Cabinet Type Centrifugal Fans in HVAC Systems

The integration of cabinet type centrifugal fans into HVAC systems is essential for several reasons:

High Pressure Capability: Designed to handle high static pressures, these fans effectively distribute conditioned air throughout large spaces, ensuring consistent temperature and comfort levels.

Versatility: They are utilized in various applications, including air handling units (AHUs), dust collection systems, and fume exhaust systems, making them suitable for diverse environments.

Efficient Airflow Distribution: Cabinet type centrifugal fans provide uniform airflow distribution, crucial for maintaining indoor air quality (IAQ) and preventing hot or cold spots in a room.

Durability: Built from robust materials, these fans withstand harsh operating conditions, reducing maintenance frequency and extending equipment lifespan.

Energy Efficiency: While they may consume more energy than axial fans, they operate efficiently under high-pressure conditions, benefiting large-scale HVAC systems.

Low Noise Levels: Generally operating at lower noise levels, especially when designed with backward-curved blades, these fans are suitable for noise-sensitive environments such as offices and hospitals.

Selecting the Right Cabinet Type Centrifugal Fan

When choosing a cabinet type centrifugal fan for your HVAC system, consider the following factors:

Airflow Requirements: Determine the volume of air that needs to be moved and select a fan that meets these specifications.

Static Pressure: Assess the static pressure requirements of your system to ensure the fan can overcome the resistance in the ductwork.

Size and Space Constraints: Ensure that the fan fits within the designated space while still meeting performance requirements.

Energy Efficiency Ratings: Look for fans that offer high energy efficiency ratings to reduce operational costs and environmental impact.

Real-world Applications

Cabinet type centrifugal fans are utilized in various sectors, showcasing their versatility and effectiveness:

Commercial Buildings: In office buildings, these fans are essential for ensuring optimal air circulation. They help maintain a comfortable indoor environment by distributing conditioned air evenly across large spaces, thus enhancing employee comfort and productivity.

Industrial Facilities: In manufacturing plants, cabinet type centrifugal fans play a crucial role in maintaining air quality and temperature control. They are often used in processes that require precise ventilation, such as in paint booths or chemical processing areas, where controlling airborne contaminants is vital.

Data Centers: These fans are critical in cooling systems for data centers, where they help prevent overheating of sensitive equipment. By ensuring a consistent airflow and temperature control, they protect valuable IT infrastructure from potential damage due to thermal stress.

Clean Rooms: In environments like pharmaceutical manufacturing or semiconductor fabrication, cabinet type centrifugal fans are used to maintain strict air quality standards. Their ability to handle particulate-laden airstreams while providing high static pressure makes them ideal for these sensitive applications.

Fume Extraction Systems: In laboratories and industrial settings, these fans are employed in fume hoods and exhaust systems to safely remove hazardous fumes and vapors, ensuring compliance with safety regulations and protecting worker health.

HVAC Systems in Hospitals: In healthcare facilities, maintaining a sterile environment is crucial. Cabinet type centrifugal fans are used in HVAC systems to provide controlled ventilation, ensuring that air quality is kept at optimal levels to support patient recovery and staff safety.

Conclusion

Cabinet type centrifugal fans play a pivotal role in enhancing the performance of HVAC systems. Their ability to provide efficient airflow, reduce energy consumption, and operate quietly makes them an invaluable asset in various applications. By understanding their features and benefits, businesses can make informed decisions that lead to improved air quality and energy efficiency.