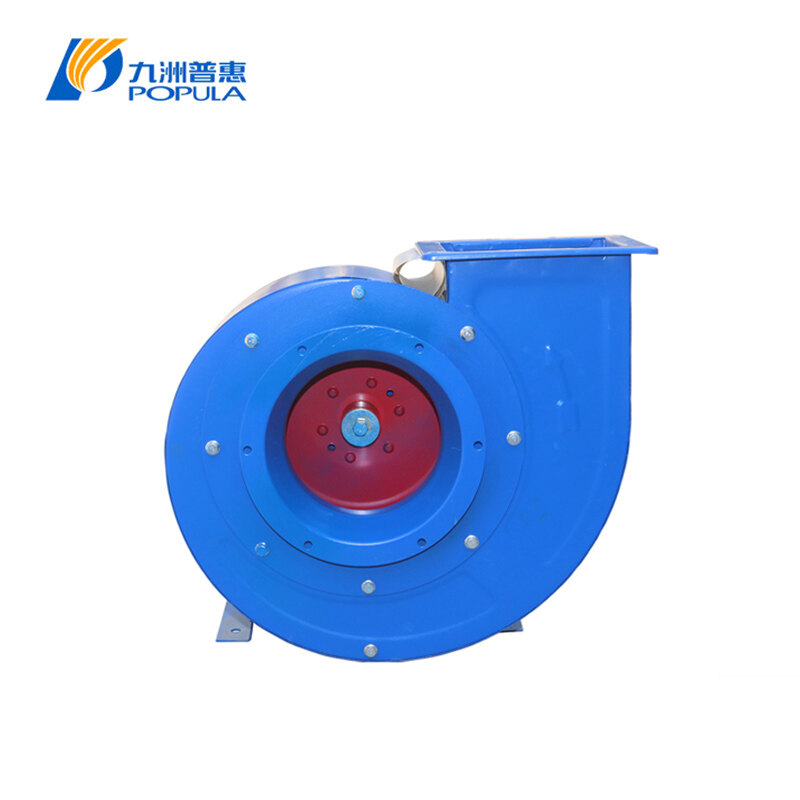

Axial flow ventilation fans always play a vital role in indoor air quality management. They are engineered to accomplish a crucial task – the controlled movement of air. Unlike their centrifugal counterparts, these fans create a unidirectional airflow path that efficiently serves a range of industrial, commercial, and residential purposes.

Operating Principles

Axial Flow vs. Centrifugal Fans

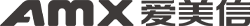

The primary distinction between axial flow and centrifugal fans lies in their operational principles.

* Axial flow ventilation fans draw air in parallel to the fan axis and discharge it in the same direction, generating a linear airflow.

* In contrast, centrifugal fans direct air through a 90-degree turn before it exits, producing a more turbulent flow. This fundamental difference influences their efficiency and application.

Key Components

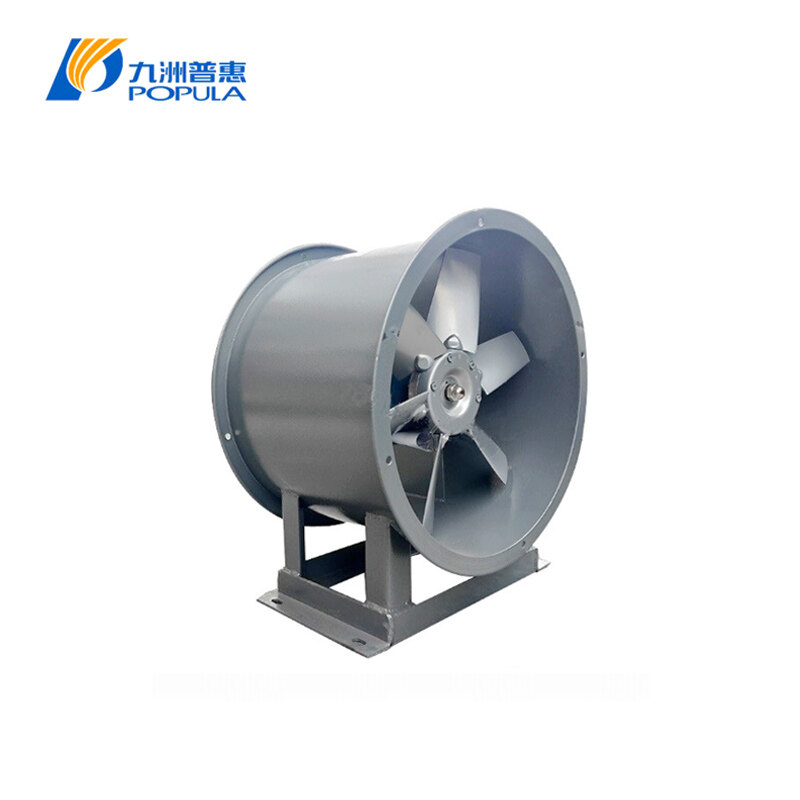

Impeller Blades

At the heart of any axial flow fan are its impeller blades, meticulously designed to ensure efficient airflow. These blades are set at a specific angle to the fan's axis and are responsible for creating the unidirectional flow. The precision engineering behind these blades optimizes the fan's performance, making it a reliable choice for various applications.

Motor and Drive System

The often-underestimated motor and drive system are essential components that power axial flow ventilation fans. The quality of these components directly affects the fan's efficiency and longevity. Regular maintenance and high-quality motors contribute to the fan's smooth operation, reducing operational downtime.

Applications and Benefits

Industrial Ventilation

Axial flow ventilation fans play a pivotal role in industrial settings. They are used to control temperature, humidity, and airborne contaminants in manufacturing facilities, warehouses, and industrial kitchens. These fans efficiently extract heat and fumes, ensuring a safe and comfortable working environment.

HVAC Systems

In the realm of heating, ventilation, and air conditioning (HVAC), axial flow ventilation fans are finding increased application in both commercial and residential systems. Their energy-efficient operation makes them an ideal choice for cooling and heating, contributing to reduced energy consumption and lower operational costs.

Energy Efficiency: Variable Speed Control

One of the standout benefits of axial flow ventilation fans is their energy efficiency. Variable speed control mechanisms allow precise adjustments to match the specific ventilation requirements. This feature significantly reduces energy consumption and contributes to sustainability efforts, making axial flow ventilation fans a compelling choice for eco-conscious consumers.

Selection and Maintenance

Sizing and Configuration

Selecting the appropriate size and configuration of an axial flow fan is essential for ensuring it meets the specific ventilation needs of a space. An undersized fan may result in inefficiencies, while an oversized one could lead to higher energy consumption. Careful consideration and consultation with experts are necessary for making the right choice.

Maintenance Best Practices

To ensure the longevity and optimal performance of axial flow ventilation fans, regular maintenance is imperative. This includes routine blade cleaning, proper lubrication of moving parts, and regular inspection of the motor and drive system. By adhering to these best practices, the fans can operate smoothly, maintaining the desired indoor air quality.

Conclusion

Axial flow ventilation fans are an essential tool for air movement and ventilation. Their operating principles, energy-efficient features, and diverse applications make them a cornerstone in maintaining comfortable and healthy environments. If you want more information about AMX axial flow ventilation fans, please feel free to contact us. We are ready to help you!