Centrifugal Cabinet Fan | Mixed Flow Inline Fan - AMX

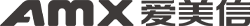

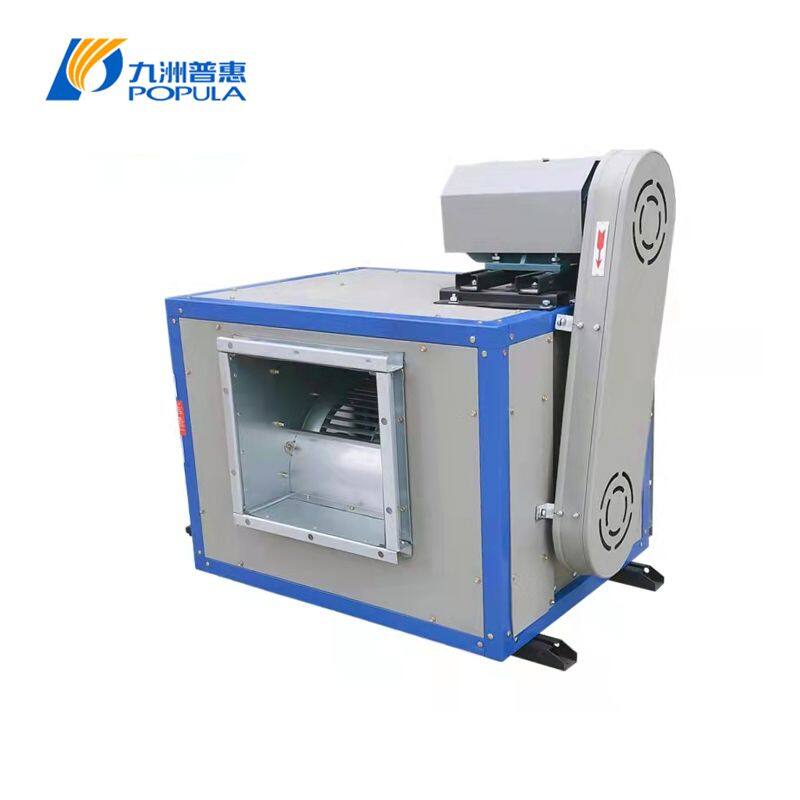

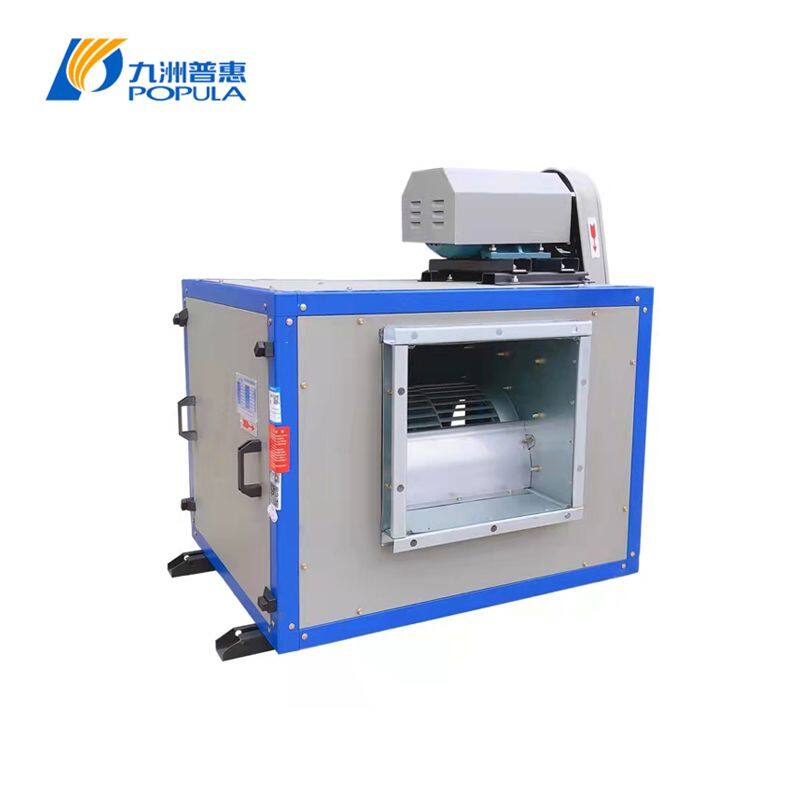

DT Model Features:

Material Properties

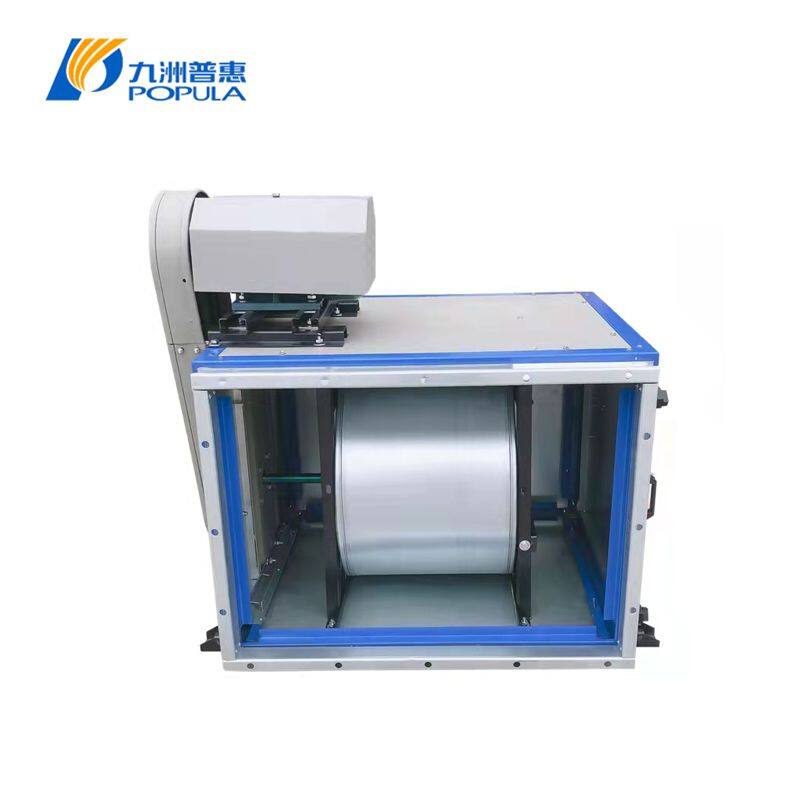

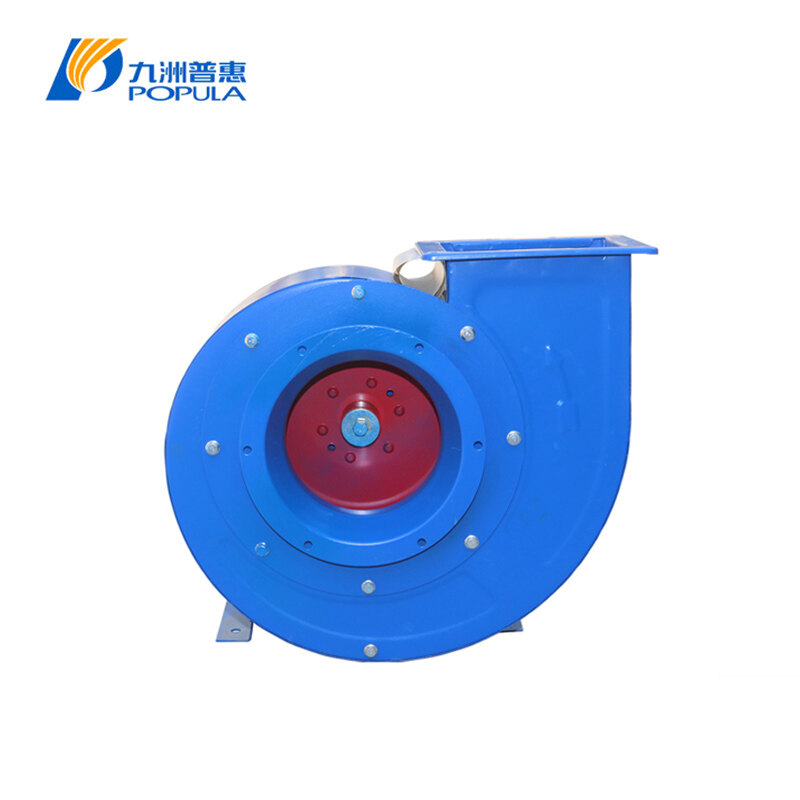

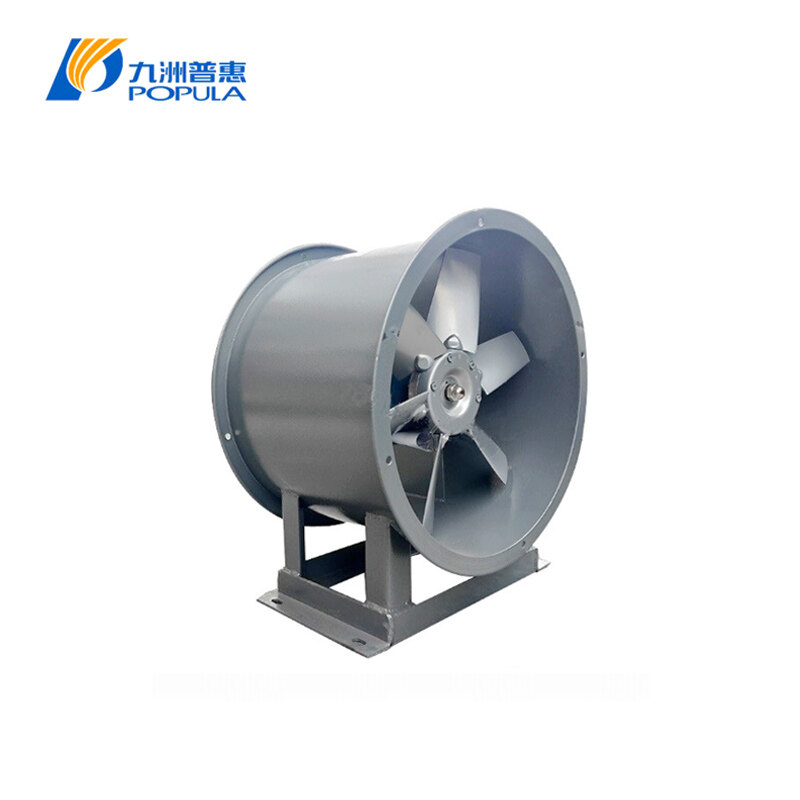

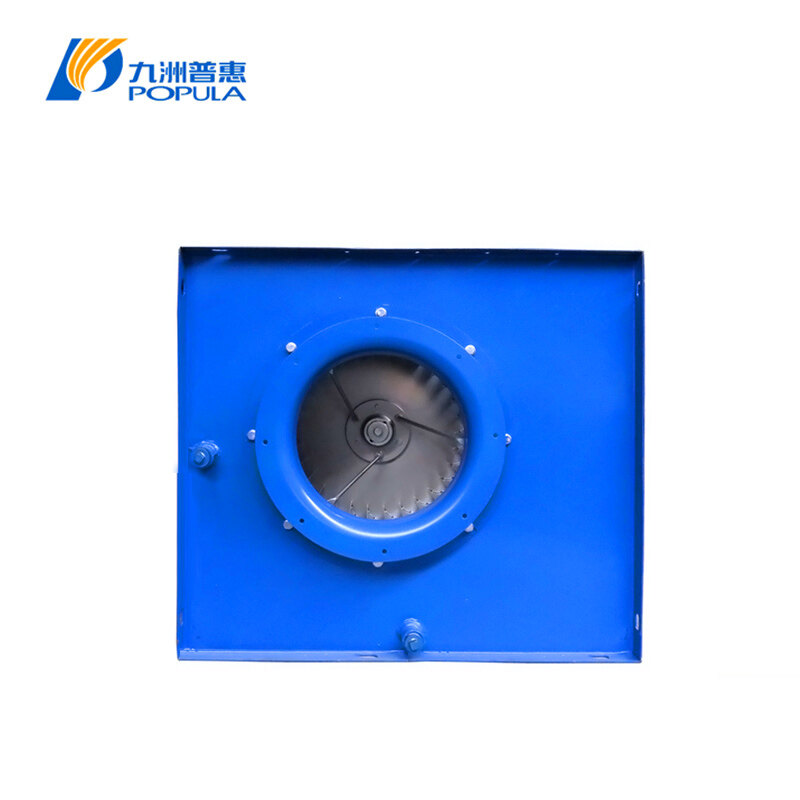

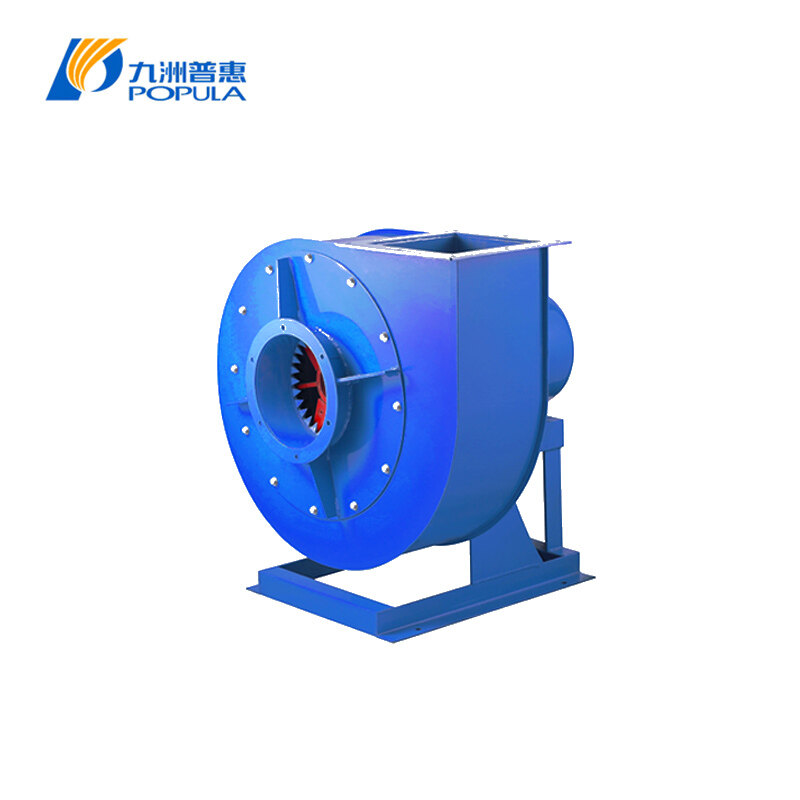

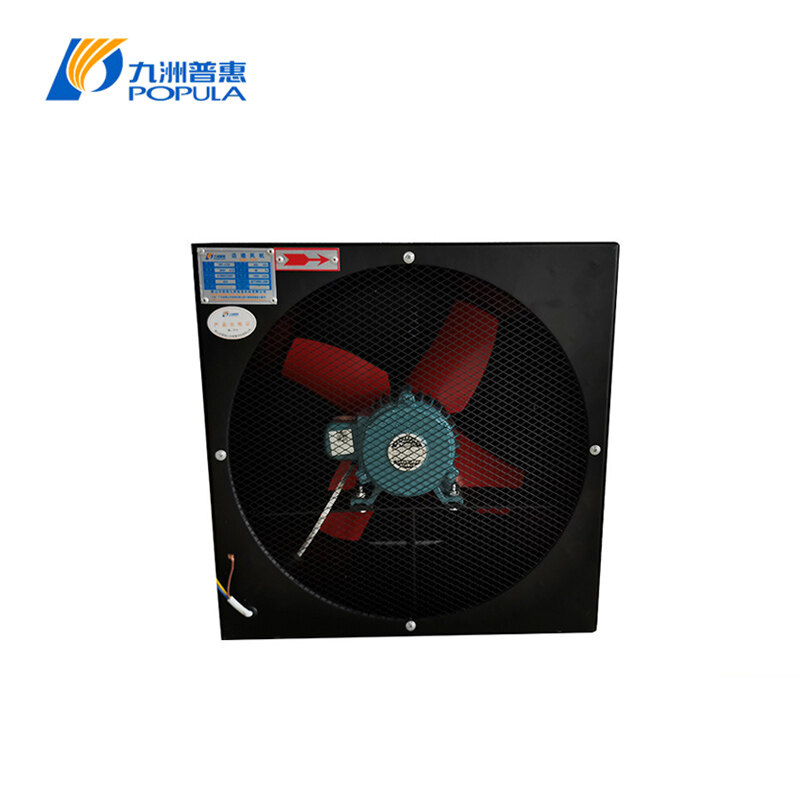

The case of this centrifugal cabinet fan is made of high-quality DKP, while the frame is made of high-quality aluminum alloy with baked paint process coating, which gives it a durable shine color. The motor is a highly efficient, 100% pure Cooper ball-bearing motor. Bearing selection and load capacity are calculated to ensure that they are within safe operating limits, hence, long life and durability. The operating temperature of this mixed flow inline fan is between -20ºC to 80ºC.

Fan Structure

The impeller of this centrifugal cabinet fan is the forward curve multi-wings type. It is low noise. The impeller is adjusted by static and dynamic balance, with good aerodynamic performance. And the quality of this mixed flow inline fan is as high as the international standard.

Usage Area

Hotels, restaurants, cinemas, halls, mining industries, buildings...This model of the centrifugal cabinet fan has double speed to choose from. This mixed flow inline fan is mainly suitable for various sizes of air conditioning and purification equipment, variable air volume air conditioning cabinet units, fan cabinet air conditioning units, central air conditioning units, and various purification equipment ventilation and air exchange, etc.

| Model | Power (KW) |

RPM (r/min) |

Volume(m³/h) | Pressure(Pa ) | St.Pressure(Pa ) |

| 9〞 | 0.55 | 900 | 1328~3171 | 218~209 | 198~154 |

| 0.75 | 1000 | 1476~3524 | 269~259 | 245~190 | |

| 1.1 | 1200 | 2346~4670 | 378~361 | 343~223 | |

| 1.5 | 1400 | 2736~5448 | 514~491 | 467~304 | |

| 10〞 | 0.75 | 900 | 2422~3905 | 215~151 | 190~87 |

| 1.1 | 1000 | 2691~4339 | 256~186 | 234~108 | |

| 1.5 | 1200 | 3229~5207 | 381~268 | 338~155 | |

| 2.2 | 1400 | 3768~6075 | 520~365 | 460~211 | |

| 12〞 | 1.1 | 800 | 3221~6025 | 251~195 | 224~107 |

| 1.5 | 900 | 2623~6778 | 315~247 | 285~135 | |

| 2.2 | 1050 | 4288~8021 | 443~345 | 398~190 | |

| 3 | 1250 | 5033~9414 | 610~475 | 549~260 | |

| 15〞 | 1.5 | 700 | 4934~8676 | 242~200 | 210~103 |

| 2.2 | 820 | 5780~10164 | 332~273 | 290~142 | |

| 3 | 850 | 6526~10977 | 393~242 | 339~170 | |

| 4 | 930 | 6910~11623 | 441~272 | 380~200 | |

| 18〞 | 2.2 | 600 | 6954~12375 | 283~203 | 240~109 |

| 3 | 720 | 8150~14507 | 393~242 | 332~149 | |

| 4 | 820 | 9404~16738 | 441~272 | 440~200 | |

| 5.5 | 930 | 10601~18869 | 657~471 | 560~252 | |

| 20〞 | 3 | 560 | 7343~15390 | 289~216 | 272~140 |

| 4 | 610 | 8412~17628 | 378~283 | 356~184 | |

| 5.5 | 720 | 9613~20146 | 495~370 | 465~240 | |

| 7.5 | 800 | 10815~22665 | 625~468 | 589~303 | |

| 22〞 | 4 | 550 | 11528~22666 | 335~218 | 307~110 |

| 5.5 | 650 | 13624~26787 | 467~305 | 428~152 | |

| 7.5 | 720 | 16831~29672 | 607~373 | 525~187 | |

| 11 | 800 | 16768~32969 | 708~460 | 650~231 | |

| 25〞 | 5.5 | 520 | 17107~27831 | 345~243 | 307~170 |

| 7.5 | 580 | 19081~31042 | 430~303 | 383~215 | |

| 11 | 650 | 21713~35324 | 556~392 | 495~278 | |

| 15 | 720 | 24016~39070 | 680~480 | 606~338 | |

| 28〞 | 7.5 | 500 | 21203~33778 | 393~355 | 351~275 |

| 11 | 560 | 24321~38745 | 523~468 | 462~360 | |

| 15 | 650 | 27439~43712 | 625~590 | 588~460 | |

| 18.5 | 720 | 30557~48680 | 825~590 | 729~578 | |

| 22 | 800 | 33675~53647 | 990~897 | 886~702 | |

| 30〞 | 11 | 500 | 24938~35334 | 494~426 | 450~360 |

| 15 | 560 | 27931~39574 | 620~535 | 564~450 | |

| 18.5 | 600 | 29926~48202 | 723~614 | 647~516 | |

| 22 | 650 | 32420~52219 | 835~720 | 760~605 | |

| 30 | 650 | 34947~57843 | 860~784 | 769~745 | |

| 33〞 | 11 | 400 | 30006~46447 | 366~303 | 318~208 |

| 15 | 450 | 34397~53244 | 481~398 | 418~273 | |

| 18.5 | 500 | 36592~56642 | 545~451 | 473~309 | |

| 22 | 550 | 38788~60041 | 612~506 | 532~347 | |

| 30 | 600 | 43179~66838 | 760~628 | 660~430 | |

| 37 | 650 | 47716~73562 | 927~766 | 804~525 | |

| 36〞 | 15 | 350 | 31926~52079 | 360~286 | 317~217 |

| 18.5 | 400 | 36487~59519 | 468~374 | 414~283 | |

| 22 | 450 | 41048~66959 | 593~474 | 524~359 | |

| 30 | 500 | 45608~74399 | 732~585 | 647~443 | |

| 37 | 550 | 50169~81839 | 886~707 | 783~536 | |

| 45 | 600 | 54730~89278 | 1054~842 | 932~638 |